Overview

Are you tired of lengthy dental visits? The article provides a comprehensive guide for busy professionals like you on mastering the process of 3D printing dentures. It details each step, from capturing impressions to final fit testing, ensuring a smooth experience. Furthermore, it emphasizes the advantages of this innovative technology. You can enjoy:

- Reduced production time and costs

- Enhanced customization

- Improved patient comfort

This means that you can embrace the growing trend of digital dentistry, which is transforming oral care solutions. Your comfort is our priority, and we understand that navigating dental options can be overwhelming. Let this guide support you in making informed choices that enhance your practice and your patients’ experiences.

Introduction

The landscape of dentistry is rapidly evolving, and we understand that navigating these changes can be daunting.

- With 3D printing emerging as a game-changer in the production of dentures, this innovative technology not only streamlines the creation process but also offers a level of customization that enhances patient comfort and satisfaction.

- Are you tired of lengthy dental visits?

- Embracing this transformation is essential, yet dental professionals face the challenge of mastering the intricate steps involved in 3D printing dentures.

- This means that understanding the essential techniques and tools required to navigate this new frontier effectively is more important than ever.

Understand 3D Printing in Dentistry

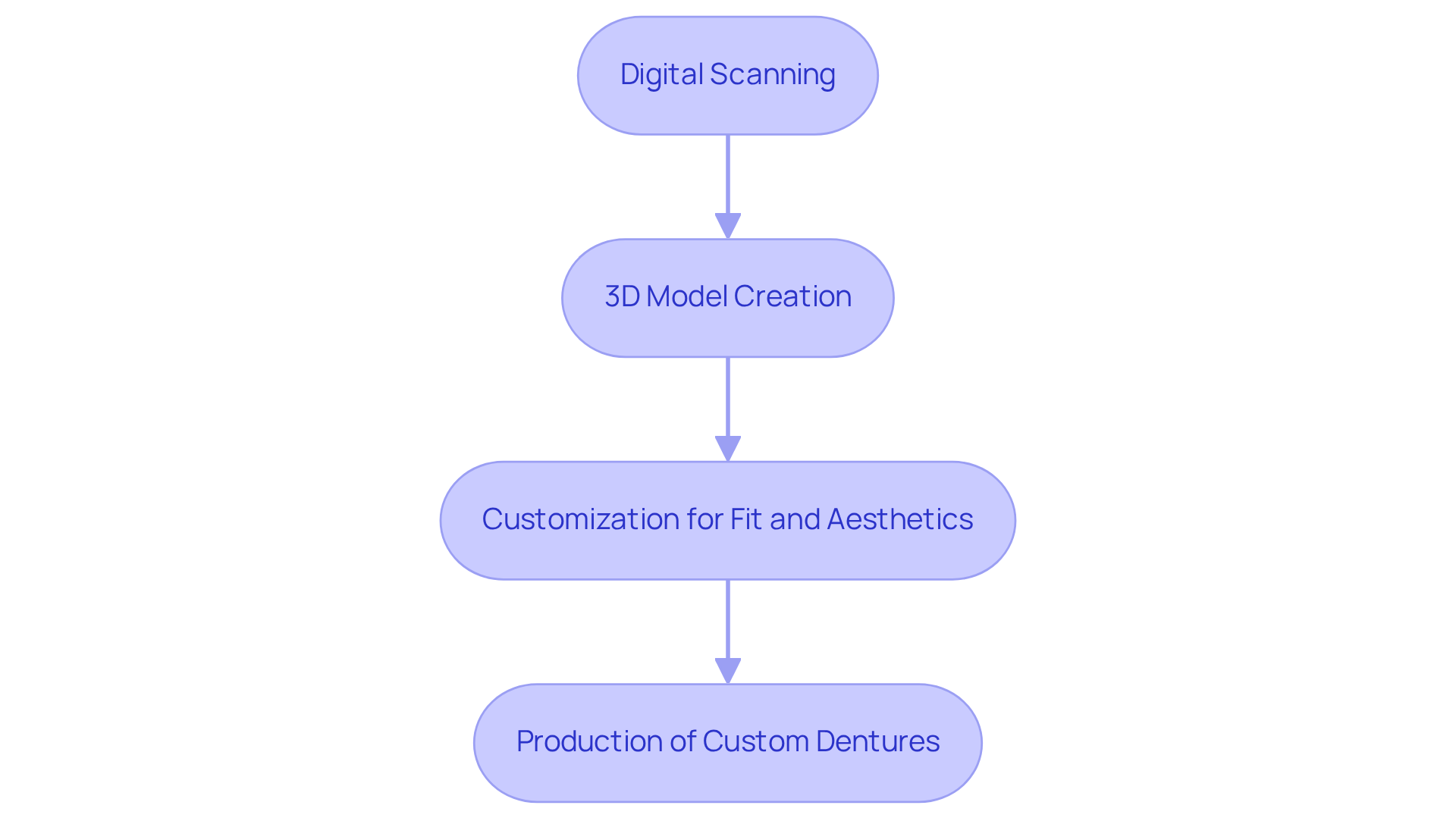

3D printing dentures in dentistry is transforming the way we produce oral products, building them layer by layer from digital models. Are you tired of lengthy dental visits? This innovative technology allows for the creation of 3D printing dentures that are highly customized to the unique contours of your mouth, perfectly aligning with DentKits’ commitment to providing affordable luxury dentures. The process begins with digital scanning, capturing the precise dimensions of your dental arch, which is then used to create a 3D model. This model can be modified to ensure optimal fit and aesthetics, enhancing your satisfaction while enabling a straightforward at-home impression process—no invasive or awkward exams required.

The advantages of 3D fabrication are considerable. It greatly decreases production time and costs while enabling the formation of intricate shapes that conventional methods struggle to achieve. This means that you can enjoy more comfortable and effective oral solutions at a fraction of the cost compared to local clinics. Dental professionals recognize that 3D printing dentures not only streamlines the manufacturing process but also improves the overall quality of care. Rune Fisker, VP of Product Strategy, observes, “The landscape of digital dentistry continues to advance quickly, with 3D fabrication technology taking on a more significant role in oral care facilities and laboratories globally.”

Furthermore, with the 3D manufacturing market exceeding $3 billion in 2023 and anticipated to grow by over 20% each year through 2032, the impact of 3D technology on oral solutions is significant, indicating a crucial shift in contemporary dentistry. Successful implementations, like SprintRay’s acquisition of EnvisionTEC’s oral portfolio, further demonstrate the practical applications and advancements in the field. We understand that your comfort is our priority, and with 3D printing dentures, we are revolutionizing care for individuals by making high-quality, more accessible than ever.

Follow the Step-by-Step Process for 3D Printed Dentures

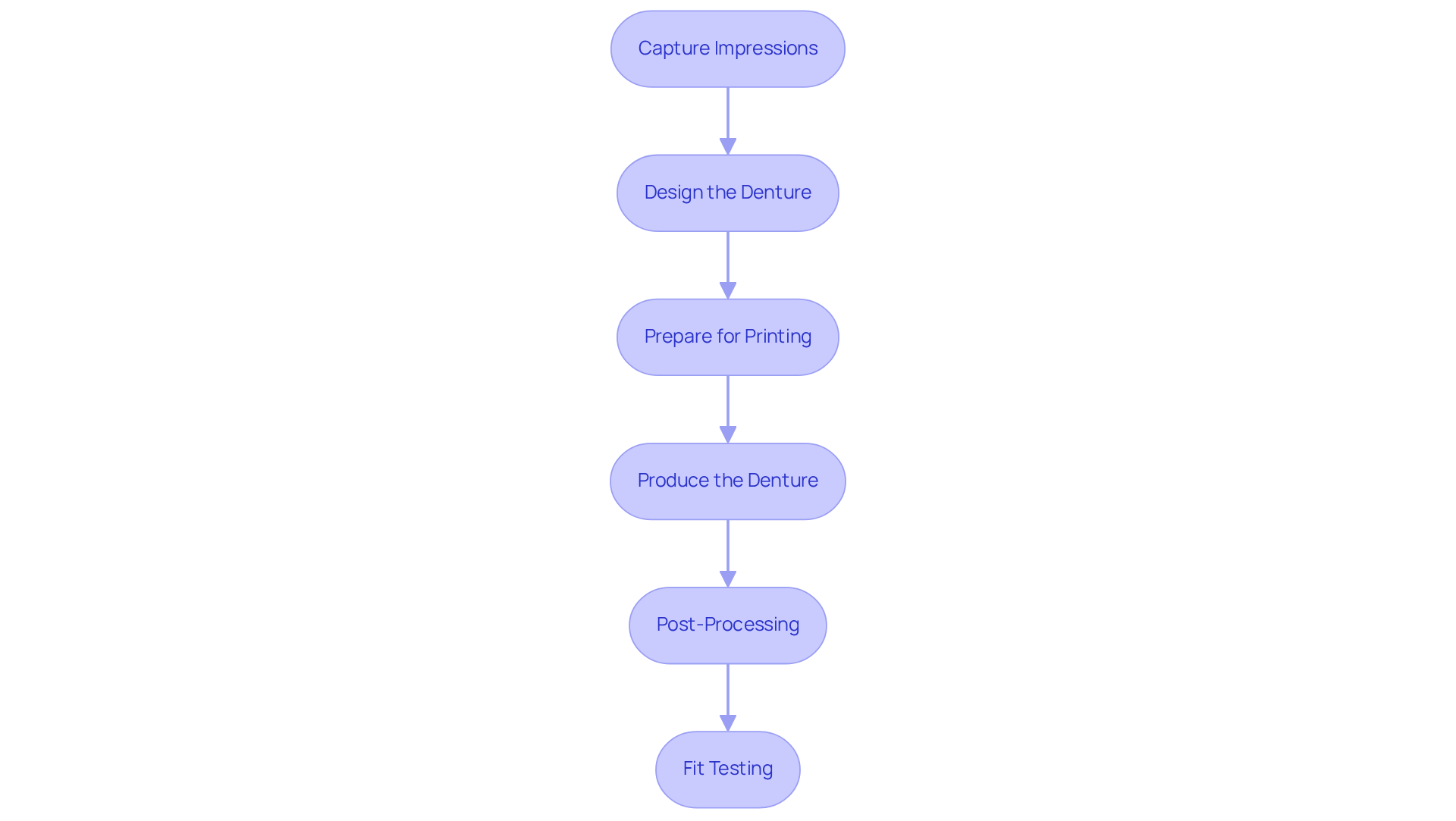

- Capture Impressions: Are you tired of lengthy dental visits? Begin by utilizing an intraoral scanner to obtain precise dental impressions. This step is crucial for creating an of your mouth, serving as the foundation for the complete prosthesis design process. Accurate impressions are vital, as they directly impact the fit and comfort of your final product. At DentKits, we understand that your comfort is our priority. That’s why we use state-of-the-art imaging cameras to create a 3D model of your teeth and gums, ensuring precision from the start.

- Design the Denture: In addition, we employ CAD software to craft the denture based on the scanned data. This design phase allows for adjustments in aesthetics and functionality, ensuring the final product aligns with your specific needs and preferences. According to dental technicians, utilizing CAD can significantly enhance the design process, reducing errors and improving outcomes. Furthermore, a U.S. in-state licensed dentist will review and prescribe your DentKits designed denture, ensuring professional oversight.

- Prepare for Printing: Next, export the finalized design as an STL file and set up the 3D printer. It’s essential to calibrate the printer and load the appropriate materials to create optimal conditions for output. This means that the use of 3D printing dentures streamlines the lab process, reducing the time needed for fabrication compared to conventional methods. At DentKits, our advanced technology for 3D printing dentures brings your designs to life efficiently.

- Produce the Denture: Begin the creation process, which may take several hours depending on the printer and materials used. Continuous monitoring during this phase is crucial to address any potential issues that may arise. Significantly, 3D printing dentures can reduce over an hour of hands-on labor compared to traditional techniques, improving efficiency and enabling faster turnaround times.

- Post-Processing: After printing, the dental appliance undergoes post-processing, which includes cleaning, curing, and polishing. These steps are essential to achieve the desired finish and enhance the longevity of your dental prosthesis. Proper post-processing guarantees that the dental appliance meets the high standards expected in modern dentistry. Our U.S.-based lab technicians meticulously build, shape, and characterize your new teeth to ensure they are strong and realistic.

- Fit Testing: Finally, conduct a fit test with you to confirm comfort and functionality. Make any necessary adjustments to ensure the appliance meets your expectations before finalizing the product. The success rates of 3D printing dentures are similar to conventional ones, making them a trustworthy option for individuals seeking contemporary oral solutions. With DentKits, you can rely on the fact that your custom dental devices are created with care and precision.

Gather Essential Tools and Resources

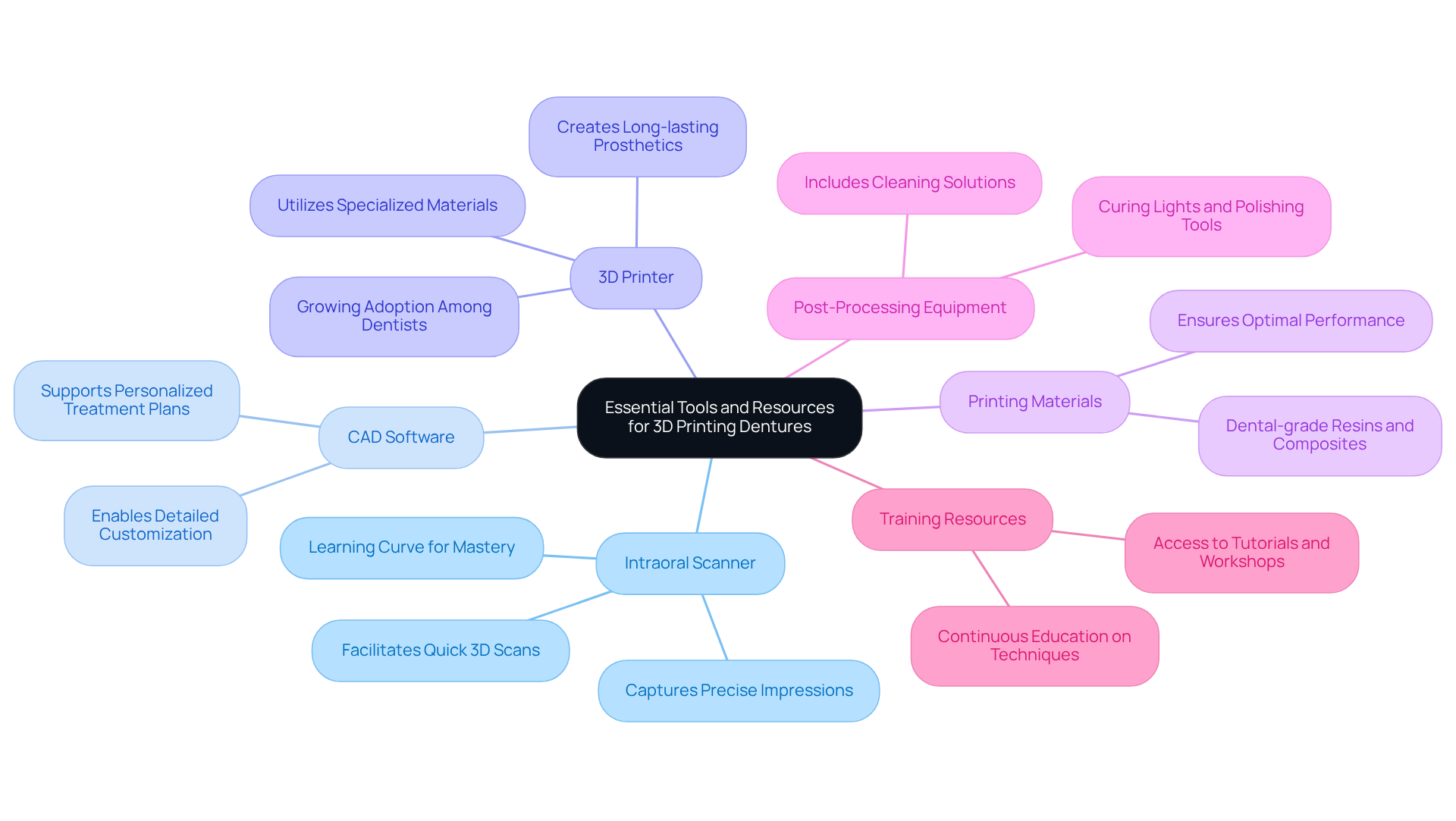

Are you tired of lengthy dental visits? To successfully create 3D printing dentures, you will need a few essential tools and resources that can make your experience smoother and more efficient.

- Intraoral Scanner: This device is crucial for capturing precise dental impressions, ensuring that the digital model accurately reflects your anatomy. DentKits simplifies this process, allowing for a quick 3D scan or impressions to be taken in your office. This accessibility is especially beneficial for busy professionals like you. However, we understand that there is a learning curve associated with mastering intraoral scanners, and not all labs may be equipped for digital design and printing.

- CAD Software: This software is vital for designing prosthetics based on scanned data. The top CAD software for oral applications enables detailed customization and modifications to meet your unique requirements. With DentKits, you can utilize to create personalized treatment plans, enhancing the customization process.

- 3D Printer: A high-quality printer is essential for creating long-lasting and visually appealing dental prosthetics. It can manage specialized materials such as resin or composite. Notably, 67% of dentists using a 3D printer have been using it for less than two years, indicating a growing trend in the adoption of this technology. DentKits’ state-of-the-art 3D fabrication technology ensures that your custom smile is brought to life efficiently.

- Printing Materials: Utilizing dental-grade resins or composites specifically formulated for 3D printing oral prosthetics is crucial for ensuring optimal performance and longevity. DentKits offers these materials as part of their comprehensive solutions, simplifying the process for your oral health practice.

- Post-Processing Equipment: This includes cleaning solutions, curing lights, and polishing tools, which are vital for finishing the dentures to a high standard. With DentKits’ approach, you can be confident that the final product meets the highest quality standards.

- Training Resources: Access to tutorials, workshops, or ongoing education on 3D printing techniques is essential for enhancing your skills and improving workflow efficiency. Continuous education is crucial as technology evolves in dental prosthetics, and DentKits supports your practice in this transition.

Furthermore, the turnaround time from consultation to final delivery of 3D printing dentures is significantly faster than traditional methods. This efficiency is particularly appealing for busy professionals. Customization options for 3D printing dentures allow for tailoring the shape, shade, and aesthetics to match your unique anatomy and preferences. Ultimately, this enhances your care and satisfaction.

Troubleshoot Common Issues in Denture Printing

When working with 3D printing dentures, it’s natural to encounter some common issues that may require specific troubleshooting approaches. Are you tired of lengthy dental visits? Let’s explore how to address these concerns compassionately.

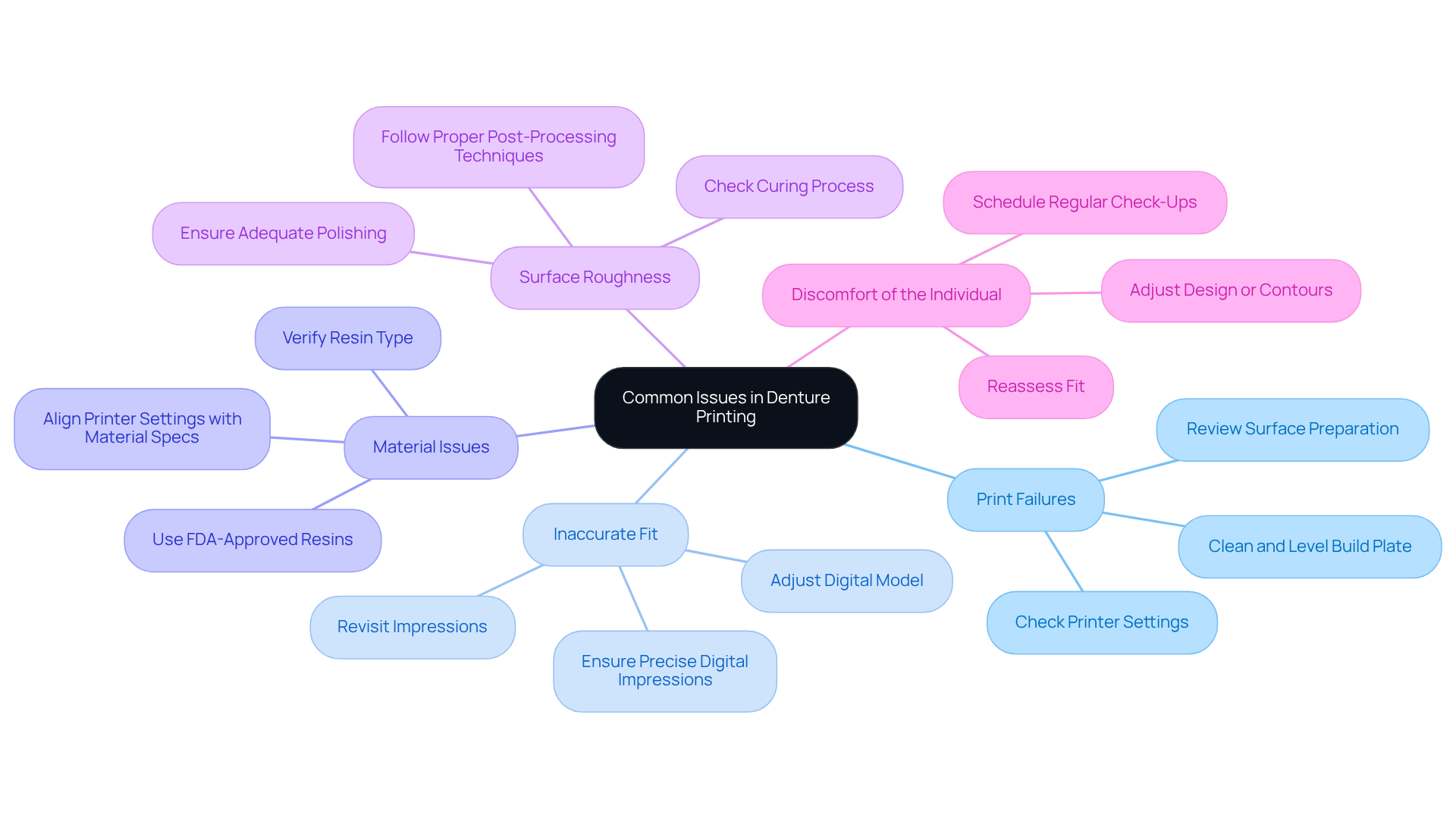

- Print Failures: If your print does not adhere properly, it’s important to check the printer settings and ensure the build plate is clean and level. Statistics indicate that improper adhesion is a frequent cause of print failures, often linked to incorrect settings or surface preparation. We understand how frustrating this can be, and taking the time to troubleshoot can lead to better results.

- Inaccurate Fit: A poorly fitting dental appliance can stem from inaccuracies in the digital model. Revisit the impressions to confirm they were captured correctly, and adjust the design as necessary. Research shows that precise digital impressions greatly improve fit and user satisfaction, ensuring that your comfort is prioritized.

- Material Issues: If the material is not curing properly, verify that you are using the correct resin and that the printer settings align with the material specifications. Recent findings highlight that using specialized, FDA-approved resins can mitigate many common material-related problems, providing peace of mind.

- Surface Roughness: A rough finish on your dental appliance can be addressed by ensuring proper post-processing techniques are followed, including adequate polishing and curing. Research indicates that surface quality directly influences comfort and satisfaction for individuals, reinforcing the importance of attention to detail.

- Discomfort of the Individual: If you or someone you know experiences discomfort, it’s essential to reassess the fit and make necessary adjustments to the design or contours of the prosthesis. Regular check-ups are vital to monitor fit and comfort, as these can change over time due to natural oral health variations.

By addressing these issues proactively, dental professionals can enhance the quality and effectiveness of 3D printing dentures, ultimately leading to improved patient outcomes. Your comfort is our priority, and we are here to .

Conclusion

The revolution in dental care brought by 3D printing technology offers a streamlined, efficient, and highly customized approach to creating dentures. Are you tired of lengthy dental visits? This innovative method not only enhances the overall patient experience by reducing the time spent in dental offices but also ensures that the final product is tailored to the unique contours of each individual’s mouth. By leveraging digital scanning, advanced design software, and state-of-the-art printing techniques, dental professionals can deliver high-quality, affordable solutions that prioritize your comfort and satisfaction.

Throughout this guide, we have detailed the step-by-step process of creating 3D printed dentures, highlighting the importance of accurate impressions, precise design, and careful post-processing. Essential tools such as intraoral scanners, CAD software, and high-quality 3D printers are crucial for successful implementation. Furthermore, common challenges in the denture printing process have been addressed, providing practical solutions to ensure optimal outcomes. The insights shared reinforce the notion that 3D printing is not merely a trend but a transformative shift in contemporary dentistry.

Embracing 3D printing technology in dental practices opens doors to enhanced patient care and operational efficiency. Your comfort is our priority, and as the market continues to expand and evolve, dental professionals are encouraged to stay informed about the latest advancements and best practices in this field. By adopting these innovative techniques, practitioners can significantly improve the quality of care provided, ensuring that every patient receives a comfortable, functional, and aesthetically pleasing dental solution. The future of dentistry is here, and it is time to take advantage of the remarkable benefits that 3D printing dentures can offer.

Frequently Asked Questions

What is 3D printing in dentistry?

3D printing in dentistry refers to the process of creating dental products, such as dentures, layer by layer from digital models. This technology allows for highly customized products that fit the unique contours of each patient’s mouth.

How does the process of 3D printing dentures work?

The process begins with digital scanning of the dental arch to capture precise dimensions. This data is used to create a 3D model, which can be modified for optimal fit and aesthetics, enabling a straightforward at-home impression process without invasive exams.

What are the advantages of 3D printing dentures?

The advantages include significantly reduced production time and costs, the ability to create intricate shapes that traditional methods cannot achieve, and improved comfort and effectiveness of oral solutions at a lower price compared to local clinics.

How does 3D printing impact the quality of dental care?

3D printing streamlines the manufacturing process and enhances the overall quality of care by providing dental professionals with more efficient tools to create high-quality, custom-fit solutions for patients.

What is the market outlook for 3D printing in dentistry?

The 3D manufacturing market in dentistry exceeded $3 billion in 2023 and is expected to grow by over 20% annually through 2032, indicating a significant shift in contemporary dentistry.

What recent developments highlight the advancements in 3D printing for dental solutions?

Successful implementations, such as SprintRay’s acquisition of EnvisionTEC’s oral portfolio, demonstrate the practical applications and advancements in the field of 3D printing in dentistry.