Introduction

Are you tired of lengthy dental visits? The world of dentistry is undergoing a remarkable transformation, thanks to the advent of 3D denture printing. This cutting-edge technology not only streamlines the denture creation process but also offers unparalleled customization, efficiency, and affordability for patients.

We understand that navigating the traditional denture acquisition process can be daunting. However, with 3D denture printing, you can take control of your oral health from the comfort of your home. This means that you can ensure both comfort and precision in your dental solutions.

This guide will delve into the essential steps for successfully navigating the 3D denture printing journey. Your comfort is our priority, and we’re here to empower you with the knowledge you need to embrace this innovative method with confidence.

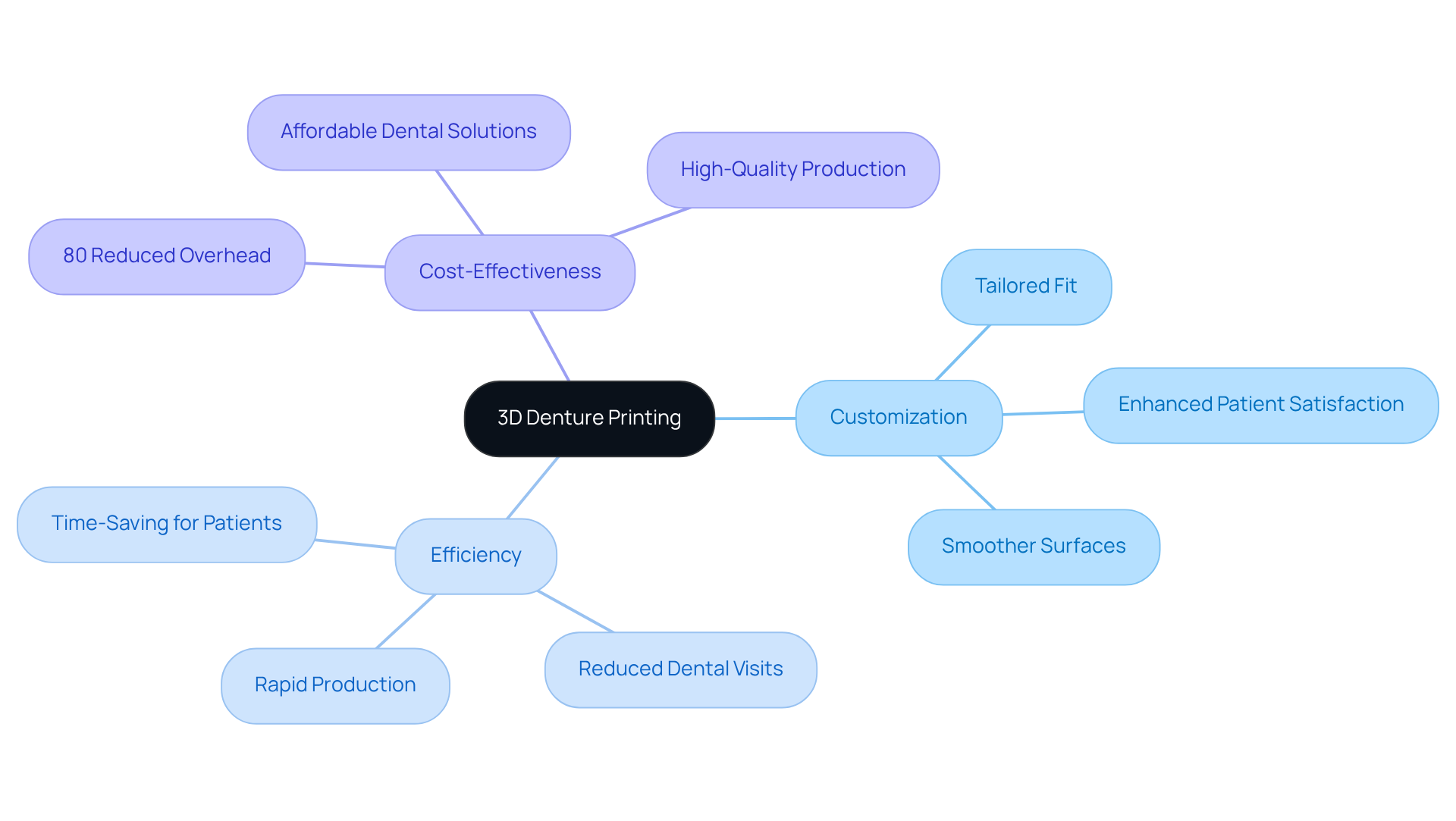

Understand 3D Denture Printing Basics

Are you tired of lengthy dental visits? 3D denture printing is here to change that. This innovative technology utilizes 3D denture printing to produce custom oral prosthetics with remarkable efficiency and precision, making the denture creation process smoother and more comfortable than ever before.

-

Customization is at the heart of this advancement. Each denture is meticulously tailored to fit your unique oral anatomy, ensuring optimal comfort and functionality. This level of personalization significantly enhances patient satisfaction, as you’ll experience smoother surfaces and accurate shapes achieved through advanced printing techniques.

-

Efficiency is another key benefit. With rapid production capabilities, 3D printing drastically reduces the time from design to delivery. Imagine walking into the office and leaving with your personalized dental appliance, often while you wait in the chair. It’s a game changer for those who value their time.

-

Cost-Effectiveness is also a major advantage. By reducing overhead expenses by as much as 80%, 3D denture printing makes high-quality dental appliances more accessible to everyone. This affordability doesn’t compromise quality; instead, it allows for the creation of aesthetically pleasing and durable dental solutions.

These fundamentals underscore the transformative impact of 3D denture printing technology in modern dentistry. We understand that your comfort is our priority, and this technology paves the way for a more streamlined and patient-centric approach to denture acquisition. Don’t wait-experience the ease and comfort of 3D denture printing today!

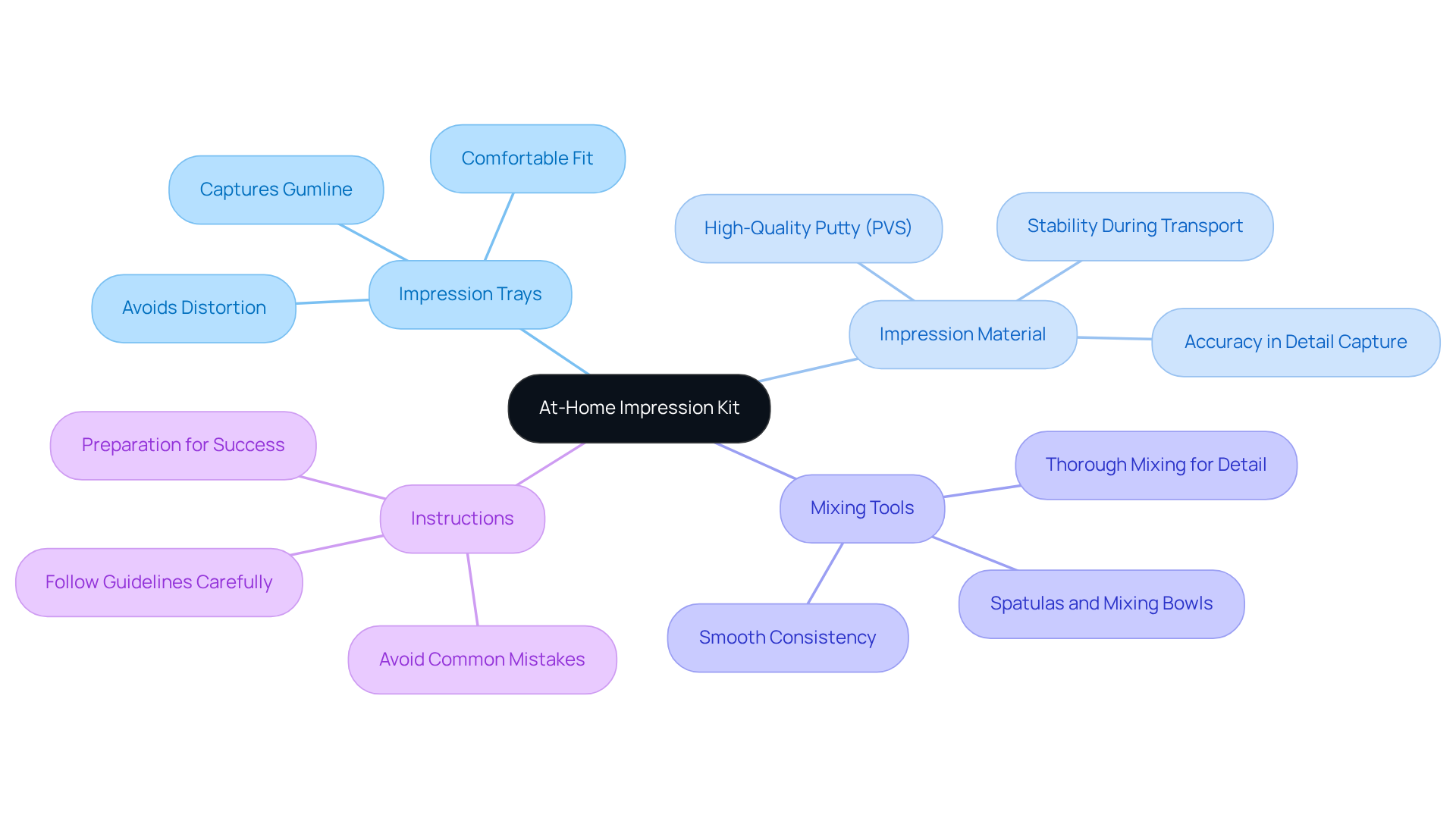

Prepare Your At-Home Impression Kit

Are you tired of lengthy dental visits? To begin your denture-making journey with DentKits, it’s essential to assemble a well-equipped at-home mold kit. Here’s what you need:

- Impression Trays: Choose trays that fit comfortably in your mouth. A proper fit is crucial for obtaining precise molds. Make sure the trays are designed to capture the gumline, which is vital for the retention of the appliance.

- Impression Material: Opt for high-quality putty, like polyvinyl siloxane (PVS). This material is recognized for its accuracy in capturing fine details and stability during transport. PVS is one of the most precise materials used for dental molds, making it a trustworthy option for your DentKits experience.

- Mixing Tools: Have spatulas or mixing bowls on hand to prepare the material thoroughly. A smooth consistency is key for optimal results. Remember, thorough mixing is essential for sharp detail and a snug fit of the appliance.

- Instructions: Carefully follow the guidelines provided with your kit. Precise outcomes rely on these instructions, as even slight variations can lead to poorly fitting dentures. Common mistakes include not combining the putty completely or removing the tray too soon, which can alter the mold.

Once your materials are gathered, take the time to familiarize yourself with the instructions. This preparation will streamline the impression-taking process, enhancing your chances of success. Many users have shared positive experiences with DentKits’ at-home kits, noting that when executed properly, the molds can compete with those made using 3d denture printing in a clinic. As dental specialists emphasize, the precision of your molds is essential for producing comfortable and functional dentures through 3d denture printing. This initial step is crucial in your path to a beautiful smile. Your comfort is our priority.

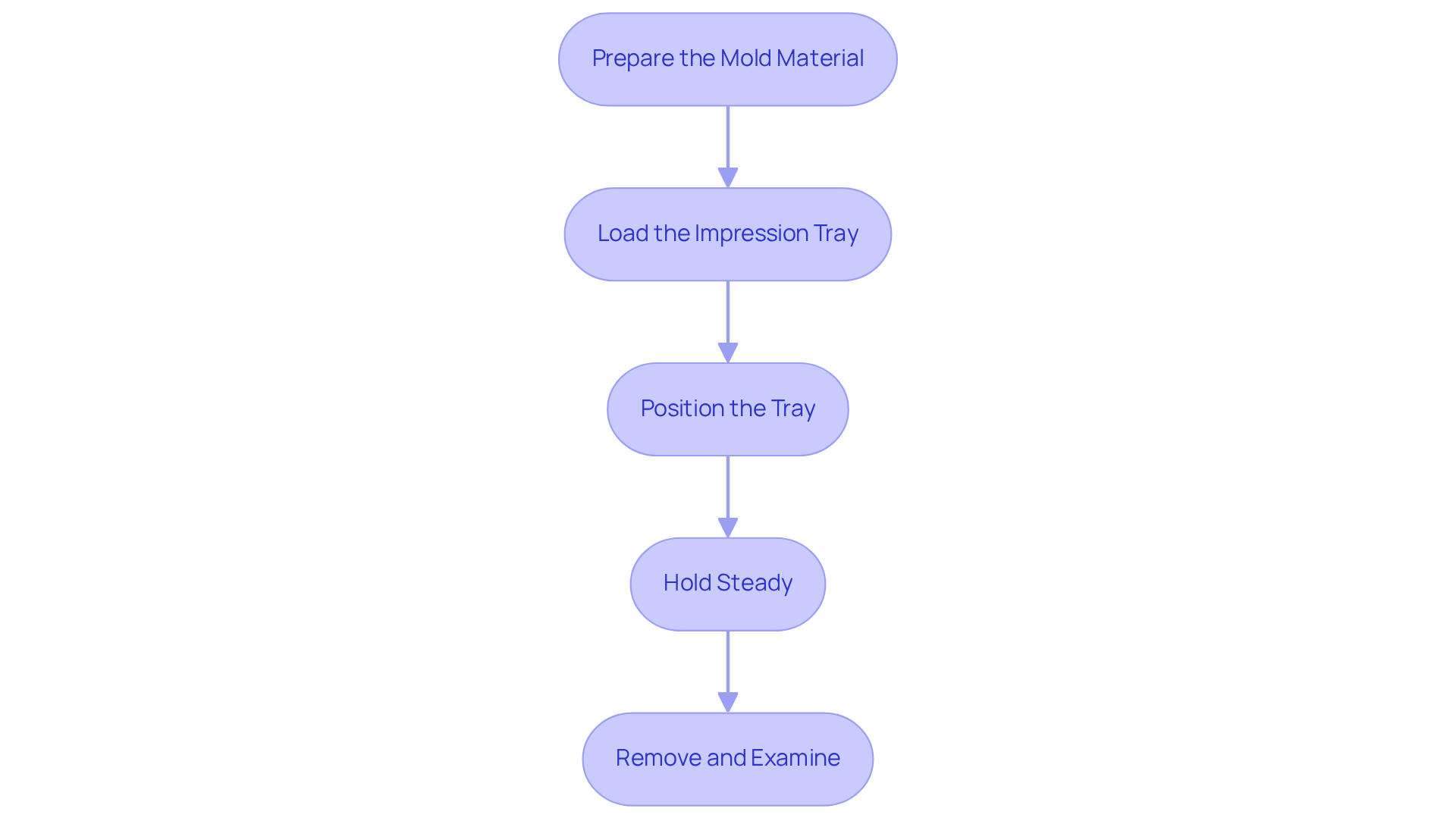

Take Accurate Digital Impressions

Are you tired of lengthy dental visits? To achieve accurate digital impressions at home, follow these essential steps that prioritize your comfort and ease:

- Prepare the Mold Material: Combine the mold material according to the provided guidelines until it reaches a uniform consistency. This ensures optimal results for your dental needs.

- Load the Impression Tray: Fill the tray with the prepared material, making sure it covers the entire surface. This step is crucial for capturing all necessary details.

- Position the Tray: Place the tray in your mouth, ensuring it adequately covers your teeth and gums. Gently bite down to create a precise mark that reflects your dental structure.

- Hold Steady: Maintain this position for the recommended time. Allow the material to set properly, capturing the intricate details of your dental structure.

- Remove and Examine: Carefully take out the tray and check the mold for any imperfections. If needed, repeat the process until you achieve a satisfactory result.

Taking your time during this process is essential. We understand that precise evaluations are important for ensuring a perfect fit for your dental appliances. Digital scans, particularly in the context of 3D denture printing, have been shown to be faster and more pleasant than traditional techniques, with many patients noting significant improvements in their overall experience. By following these steps, you can enhance the quality of your oral molds with 3D denture printing, leading to better-fitting prosthetics and a more gratifying result. Your comfort is our priority!

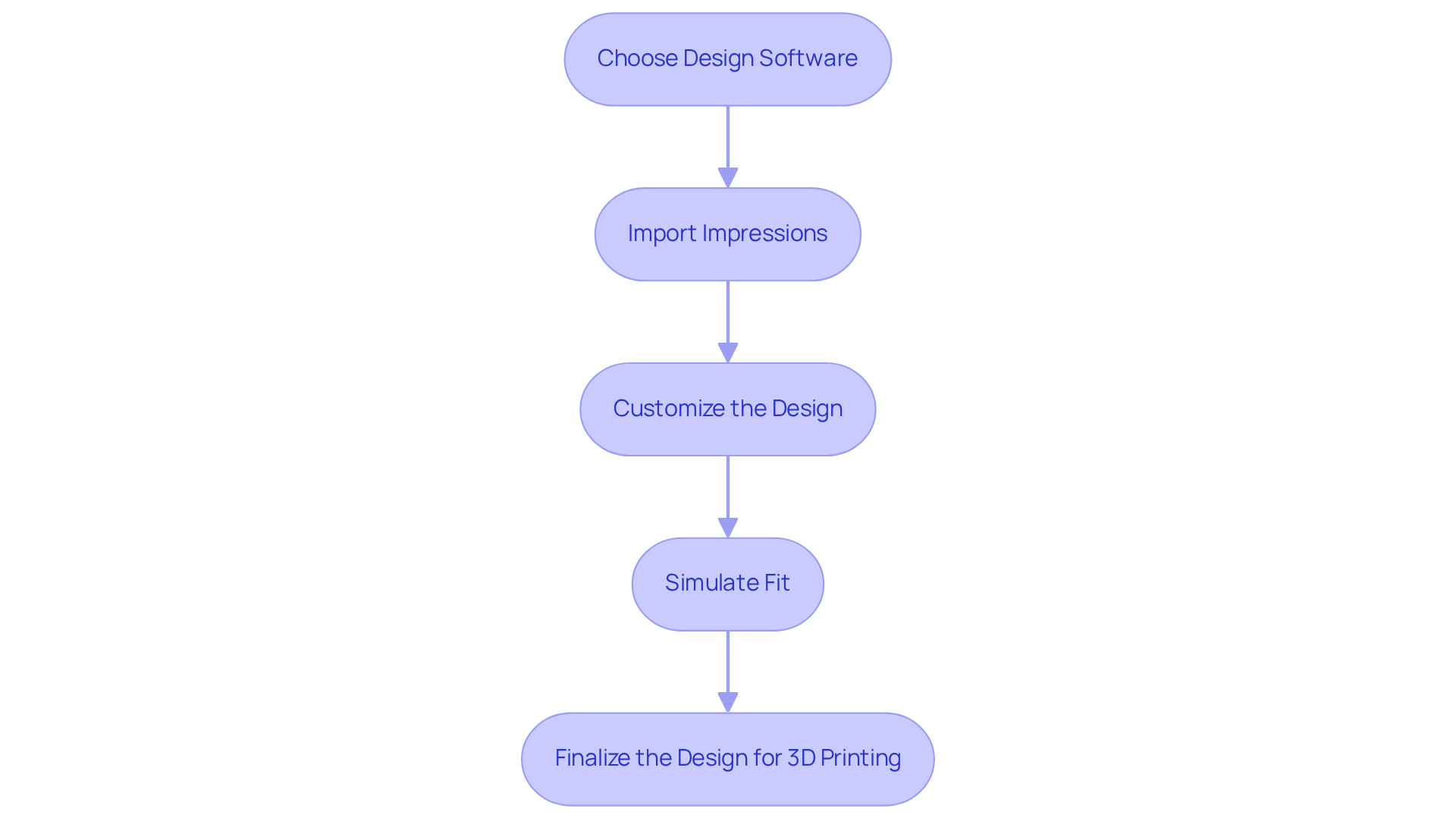

Design Your Custom Dentures

Are you tired of lengthy dental visits? The experience of designing your custom dentures can be straightforward and comforting with 3D denture printing. Here’s how you can do it in just a few simple steps:

- Choose Design Software: Start with user-friendly CAD software designed for dental applications. Notable options like 3Shape and Exocad are recognized for their intuitive interfaces and robust features, making the process easier for you.

- Import Impressions: Upload your digital impressions into the software. This process utilizes 3D denture printing to generate a precise model of your mouth, ensuring an accurate design tailored just for you.

- Customize the Design: Now, let’s personalize your dental appliance. Adjust elements such as tooth shape, size, and gum color to reflect your unique style and comfort.

- Simulate Fit: Use the software’s simulation tools to visualize how the dental prosthetics will fit and look in your mouth. This means you can confirm they meet both your aesthetic and functional needs.

- Finalize the design for 3D denture printing: Once you’re happy with the adjustments, save the design file for printing.

This process not only helps you design dental prosthetics that enhance your smile but also accommodates your distinct preferences. Your comfort is our priority, ensuring a customized fit that feels just right.

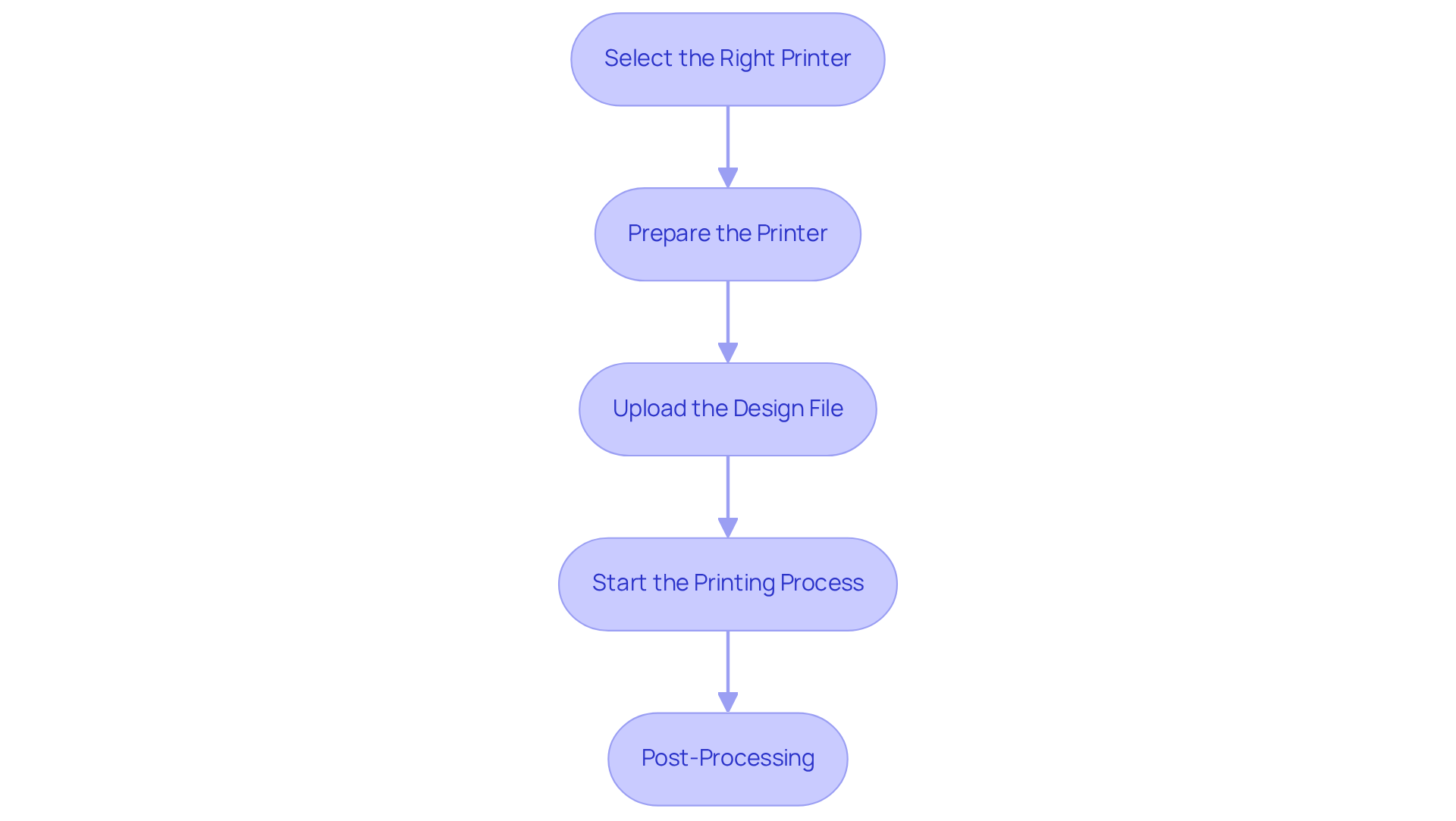

Print and Manufacture Your Dentures

Are you tired of lengthy dental visits? At DentKits, we understand that the process of getting dentures can be daunting. That’s why we’ve streamlined it for you. Here’s how you can print and manufacture your dentures with us:

-

Select the Right Printer: Choose a 3D printer that’s compatible with materials for oral use, like the Formlabs Form 3 or the Stratasys J5 DentaJet, which are ideal for 3D denture printing. These printers are known for their precision in oral applications, ensuring your dentures are crafted with care.

-

Prepare the Printer: Load the suitable resin or material for dental appliance printing. It’s crucial that this material adheres to FDA standards for oral use, as your safety and the reliability of the product are our top priorities.

-

Upload the Design File: Import your finalized design file into the printer’s software. Make sure it’s optimized for 3D printing to achieve the best results. At DentKits, we ensure a precise fit tailored just for you through 3D denture printing, which involves creating a 3D representation of your teeth and/or gums by scanning your impressions with advanced imaging cameras.

-

Start the Printing Process: Initiate the printing process while closely monitoring for any issues that may arise. Quality control is essential. A licensed dentist will review and prescribe your DentKits-designed dental appliance, ensuring it meets your specific needs.

-

Post-Processing: After printing, follow the manufacturer’s guidelines for cleaning and curing the oral prosthetics. This step is vital for enhancing durability and aesthetics. With advancements in resin shades and post-processing techniques, we can significantly improve the final product’s quality and appearance.

The process of 3D denture printing transforms your digital design into a physical product, ready for fitting and use. It showcases DentKits’ commitment to innovative 3D digitization and custom dental appliance creation, all while prioritizing your comfort and ease.

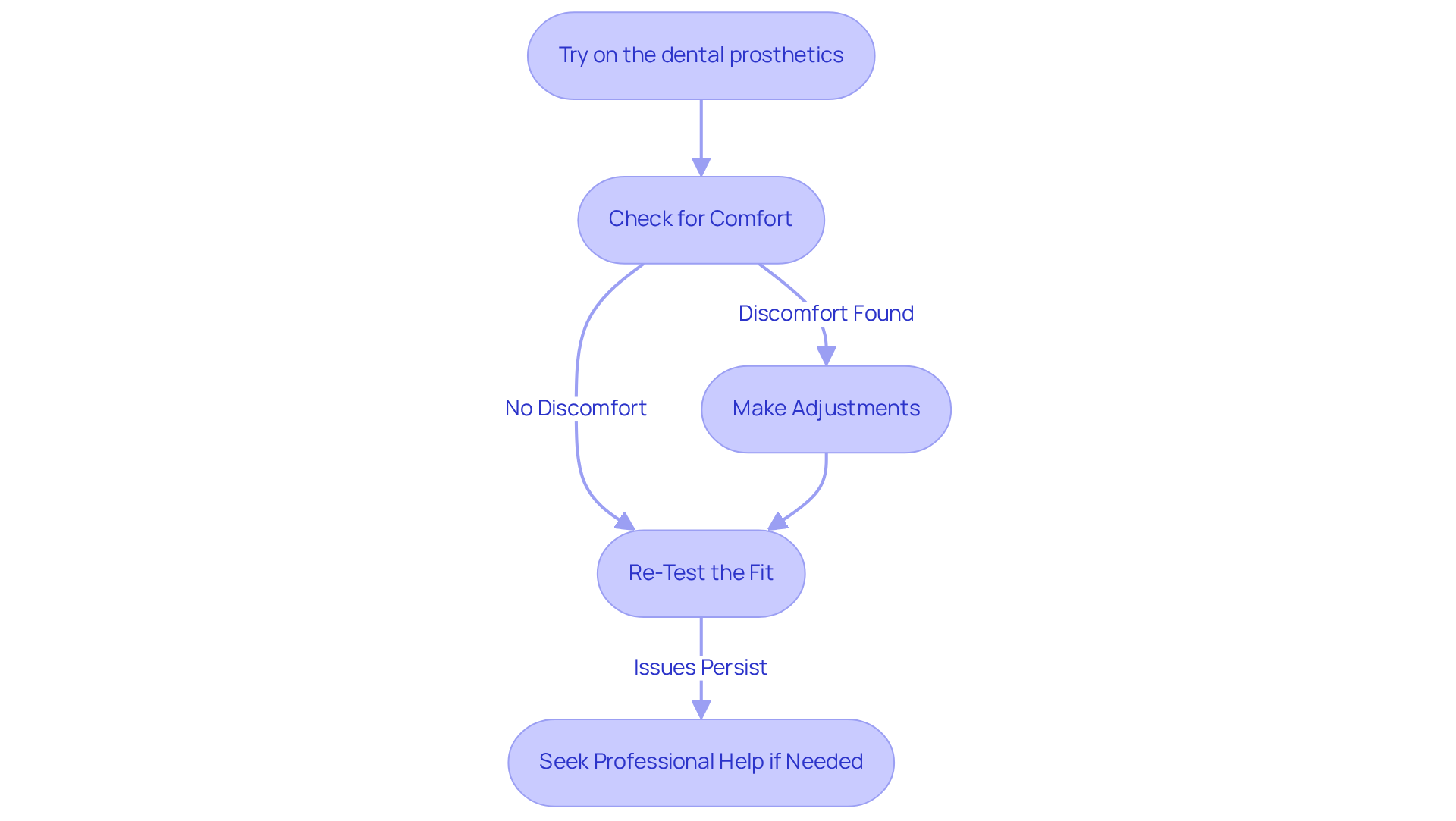

Finalize Fit and Adjust Your Dentures

To achieve the ideal fit and comfort for your dentures, follow these essential steps:

- Try on the dental prosthetics: Carefully place them in your mouth to evaluate the fit.

- Check for Comfort: Are there any areas that feel tight or cause discomfort? Pay close attention to these spots and mark them for adjustment.

- Make Adjustments: Use a tool or file to gently modify the areas causing discomfort, ensuring you don’t remove excessive material.

- Re-Test the Fit: After making adjustments, try the prosthetic on again to confirm they fit comfortably.

- Seek Professional Help if Needed: If you experience significant issues, don’t hesitate to consult a dental professional for further adjustments.

Regular adjustments are essential for preserving the comfort and functionality of your dental prosthetics. Many users report that timely modifications not only enhance their daily lives but also boost their confidence in their smiles. Remember, if you notice signs such as discomfort, frequent slipping, or difficulty chewing, it’s important to address these issues promptly. Your comfort is our priority, so ensure optimal oral health and satisfaction with your dentures.

Conclusion

Are you tired of lengthy dental visits? The journey to mastering 3D denture printing at home opens a world of convenience, personalization, and efficiency in dental care. This innovative approach transforms the way dentures are created, prioritizing your comfort and satisfaction. Imagine enjoying custom-fitted dentures that enhance both functionality and aesthetics, all from the comfort of your own home.

Throughout this article, we’ve highlighted key aspects of 3D denture printing, including the importance of accurate impressions and the selection of appropriate design software. Each meticulous step involved in printing and adjusting dentures underscores the potential for achieving high-quality results tailored to your personal needs. Furthermore, the cost-effectiveness and efficiency of this method emphasize its value in modern dentistry.

As the landscape of dental care continues to evolve, the significance of 3D denture printing cannot be overstated. It represents a significant advancement that streamlines the process of acquiring dentures and empowers you to take control of your oral health. Embracing this technology encourages a proactive approach to dental care, enhancing your overall quality of life. Whether you’re seeking to improve your smile or simply looking for a more efficient dental solution, 3D denture printing stands as a remarkable option worth exploring. Your comfort is our priority, and we invite you to take the next step towards a more convenient dental experience.

Frequently Asked Questions

What is 3D denture printing and how does it benefit patients?

3D denture printing is an innovative technology that produces custom oral prosthetics with efficiency and precision. It benefits patients by providing personalized dentures that fit their unique oral anatomy, enhancing comfort and functionality, reducing the time from design to delivery, and making high-quality dental appliances more accessible and affordable.

How does customization work in 3D denture printing?

Customization in 3D denture printing involves tailoring each denture to fit the patient’s unique oral anatomy. This meticulous process ensures optimal comfort and functionality, resulting in smoother surfaces and accurate shapes achieved through advanced printing techniques.

What are the efficiency advantages of 3D denture printing?

The efficiency of 3D denture printing allows for rapid production capabilities, significantly reducing the time from design to delivery. Patients can often walk into the dental office and leave with their personalized dental appliance, sometimes while they wait in the chair.

How does 3D denture printing affect the cost of dental appliances?

3D denture printing can reduce overhead expenses by as much as 80%, making high-quality dental appliances more affordable. This cost-effectiveness does not compromise quality; instead, it allows for the creation of aesthetically pleasing and durable dental solutions.

What materials are needed for the at-home impression kit for DentKits?

The at-home impression kit for DentKits requires impression trays, high-quality impression material like polyvinyl siloxane (PVS), mixing tools such as spatulas or mixing bowls, and instructions for use.

Why is it important to choose the right impression trays?

Choosing the right impression trays is crucial for obtaining precise molds. A proper fit ensures that the trays capture the gumline accurately, which is vital for the retention of the dental appliance.

What role does the impression material play in the denture-making process?

The impression material, particularly polyvinyl siloxane (PVS), is essential for capturing fine details and ensuring stability during transport. It is recognized for its accuracy, which is critical for producing well-fitting dentures.

What common mistakes should be avoided when taking impressions at home?

Common mistakes include not thoroughly mixing the putty, which can lead to poor detail and fit, and removing the tray too soon, which can alter the mold. Following the provided instructions carefully is essential for achieving precise outcomes.

How do at-home molds compare to those made in a clinic?

When executed properly, at-home molds using DentKits can compete with those made using 3D denture printing in a clinic, as the precision of the molds is crucial for producing comfortable and functional dentures.