Introduction

Denture 3D printing is changing the game for dental prosthetics, offering a modern solution to the often tedious and uncomfortable traditional methods. Are you tired of lengthy dental visits? By harnessing advanced digital technology, this innovative process not only streamlines the creation of custom dentures but also enhances their fit and aesthetic appeal.

However, as you explore this promising avenue, you might wonder: can the convenience of home fabrication truly match the precision of professional dental care? This means that while you can create your own dentures at home, it’s essential to consider the level of expertise involved.

In this article, we’ll delve into the world of 3D printed dentures, guiding you through the steps to create your own. We understand that navigating this new territory can be daunting, so we’ll also address the potential challenges and benefits of this cutting-edge approach. Your comfort is our priority, and we’re here to support you every step of the way.

Understand 3D Printed Dentures

Are you tired of lengthy dental visits? Denture 3D printing provides a compassionate solution by utilizing advanced digital technology to ensure accurate customization tailored to your unique oral anatomy. Unlike traditional false teeth, which often require multiple fittings and adjustments, denture 3D printing allows for swift design and production, resulting in a more comfortable and precise fit.

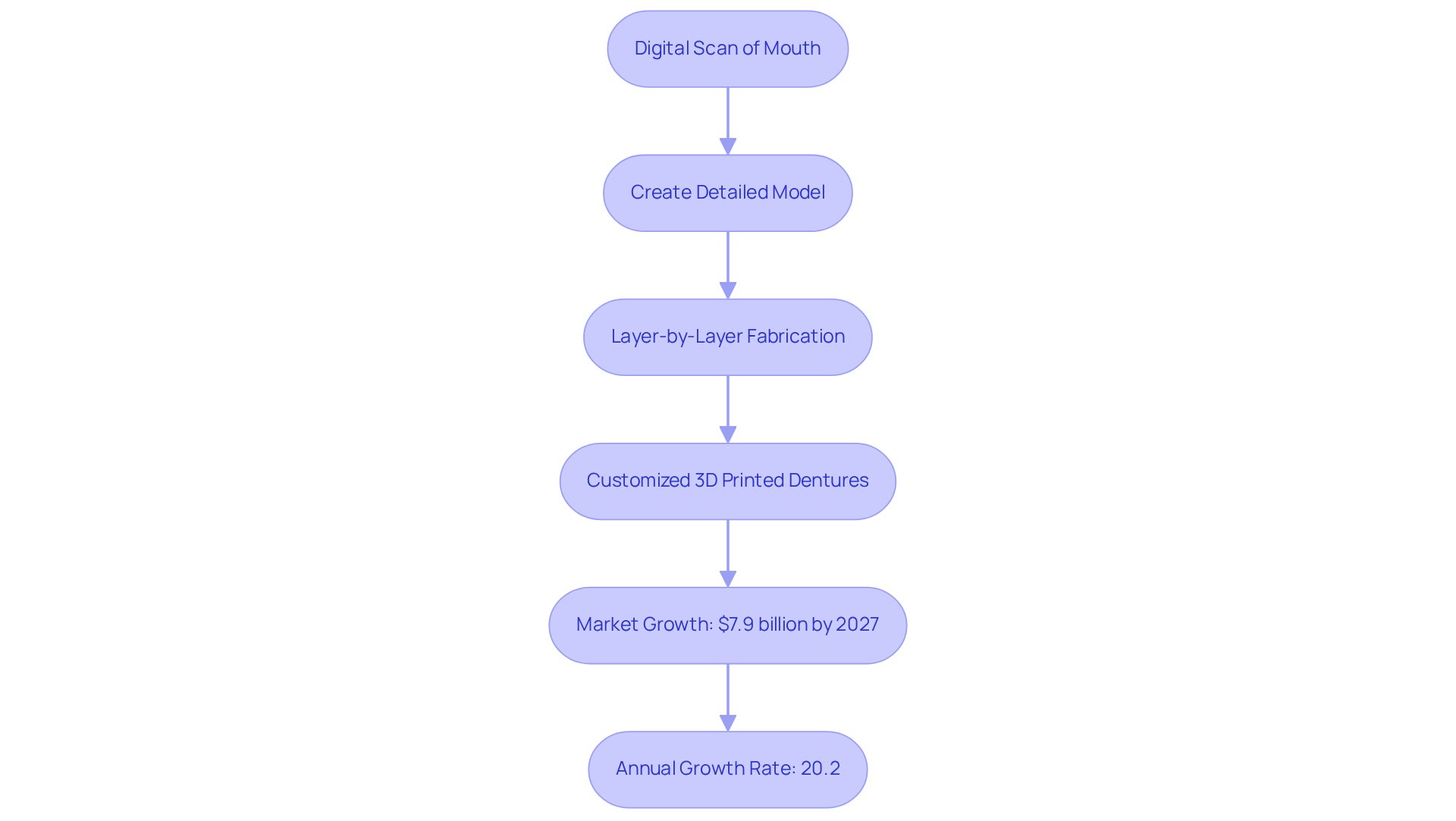

This innovative approach begins with a digital scan of your mouth, creating a detailed model that guides the layer-by-layer fabrication of dental prosthetics through denture 3D printing with biocompatible materials. This means that not only is production time significantly reduced, but the visual appeal and functionality of your dental prosthetics are also enhanced.

According to industry insights, the denture 3D printing market for dentistry is projected to reach $7.9 billion by 2027, growing at an impressive annual rate of 20.2%. Such advancements highlight the increasing preference among patients seeking luxurious and effective oral solutions for denture 3D printing. Furthermore, oral health specialists have noted that denture 3D printing technologies enhance customization options, allowing for a more personalized fit that meets your unique needs.

Your comfort is our priority, and with 3D printed dental prosthetics, you can experience a solution that not only meets your expectations but exceeds them. Embrace the future of dental care and discover how these advancements can transform your experience.

Gather Essential Materials and Tools

Creating your custom dentures at home can feel daunting, but with the right materials and tools, you can make the process smoother and more comfortable. Are you tired of lengthy dental visits? Let’s explore what you’ll need to get started.

-

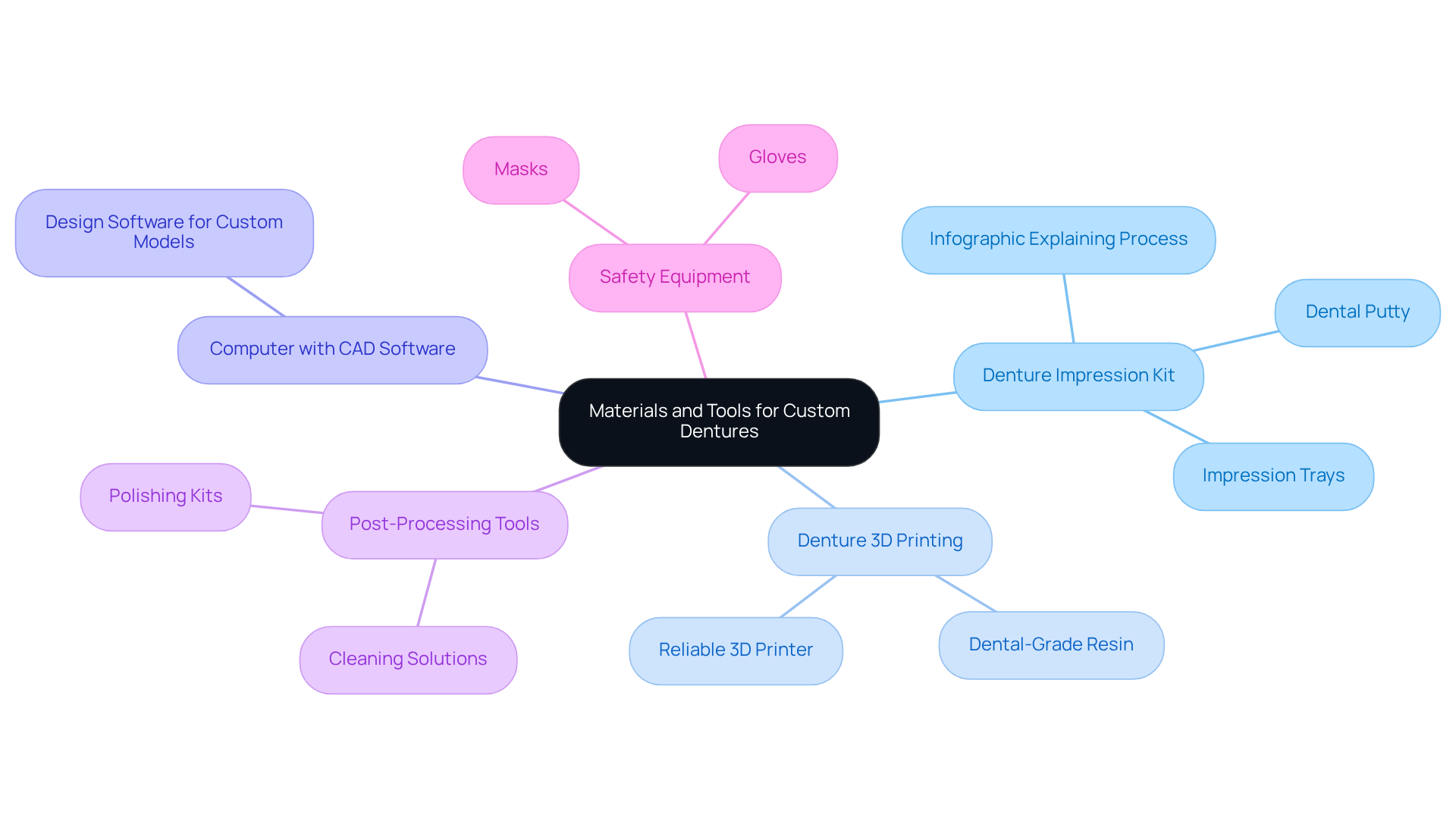

Denture Impression Kit: This kit usually includes impression trays and dental putty, which are essential for capturing accurate impressions of your teeth and gums. Having the right kit ensures that your impressions are precise, setting the foundation for your dentures.

-

Denture 3D Printing: A reliable 3D printer that uses dental-grade resin is crucial for the process of crafting high-quality prosthetics. This means you can use denture 3D printing to create dentures that meet professional standards right from the comfort of your home.

-

Computer with CAD Software: You’ll need design software to create a model of your dental appliance based on the impressions you’ve taken. This allows for precise customization, ensuring your dentures fit comfortably.

-

Post-Processing Tools: After creating your dentures, polishing kits and cleaning solutions are necessary to finish them off. This step is vital for ensuring your prosthetics are smooth and hygienic for use.

-

Safety Equipment: Don’t forget gloves and masks! These are essential for maintaining hygiene throughout the process, protecting both you and your materials.

Having these materials ready will not only streamline the denture creation process but also enhance your chances of achieving optimal results. Your comfort is our priority, so take the first step towards a more convenient denture solution today!

Take Accurate Impressions at Home

Are you tired of lengthy dental visits? Achieving accurate impressions at home has never been easier, thanks to DentKits’ innovative denture 3D printing technology. By following these simple steps, you can create precise molds that lead to comfortable, well-fitted prosthetics.

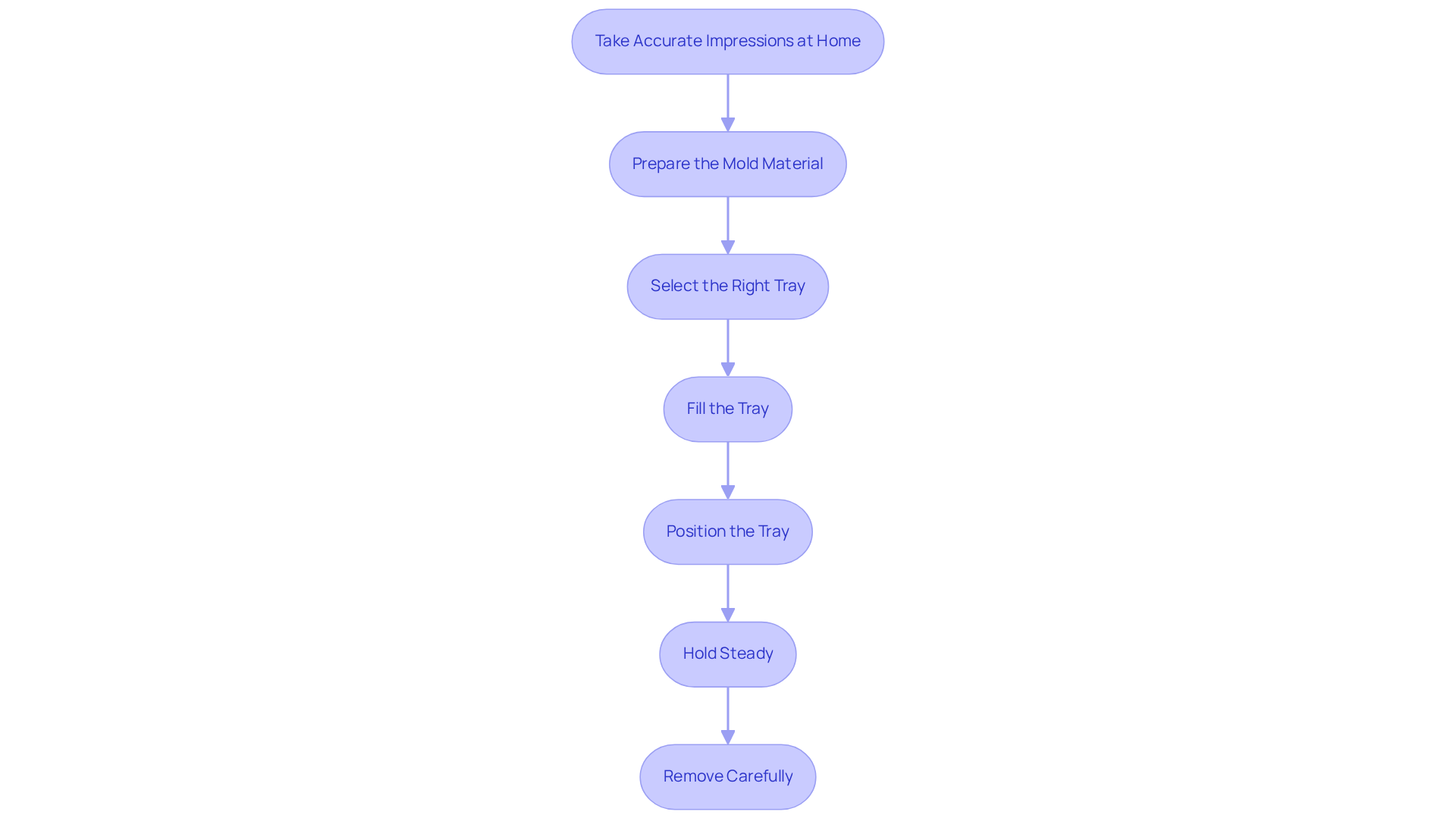

- Prepare the Mold Material: Start by carefully blending the putty according to the guidelines in your mold kit. Make sure it has a uniform texture, free of streaks. When mixed properly, the material should display a consistent color and texture.

- Select the Right Tray: Choose a tray that fits comfortably in your mouth. This helps minimize the risk of gagging during the process.

- Fill the Tray: Generously fill the tray with the mixed putty, ensuring you eliminate any air bubbles. Dental professionals emphasize that avoiding air bubbles is crucial for achieving a precise mold.

- Position the Tray: Center the tray over your teeth and gums, gently biting down to ensure full contact with the material.

- Hold Steady: Keep the tray in place for the recommended duration (typically 3-5 minutes) until the putty has fully set. This ensures a precise mold.

- Remove Carefully: Gently wiggle the tray to break the seal before removing it from your mouth. Examine the print for clarity and detail, ensuring it captures all necessary features.

Repeat this process for both the upper and lower arches to acquire thorough molds.

We understand that common errors in creating oral molds can lead to poorly fitting prosthetics. Insufficient blending of substances or not allowing enough time for the putty to cure can cause issues. To avoid these pitfalls, follow the mixing instructions closely and allow the putty to cure fully before removal. Additionally, managing your breathing and staying calm can help mitigate any gag reflex during the impression-taking process.

Success stories show that many individuals have achieved precise dental molds at home by following these recommendations, resulting in well-fitted and comfortable prosthetics. As dental experts indicate, a properly fitted dental prosthesis improves chewing effectiveness and overall satisfaction with the oral device. However, it’s essential to be aware of potential risks associated with taking molds, such as distortion from movement or improper handling, to ensure the best outcomes.

The designs you create will be utilized in the sophisticated denture 3D printing process to craft your personalized dental devices, showcasing the cutting-edge technology that DentKits employs. Your comfort is our priority, and we’re here to support you every step of the way.

Customize Your Dentures for a Perfect Fit

Are you tired of lengthy dental visits? After obtaining your impressions, you can personalize your dentures by following these essential steps:

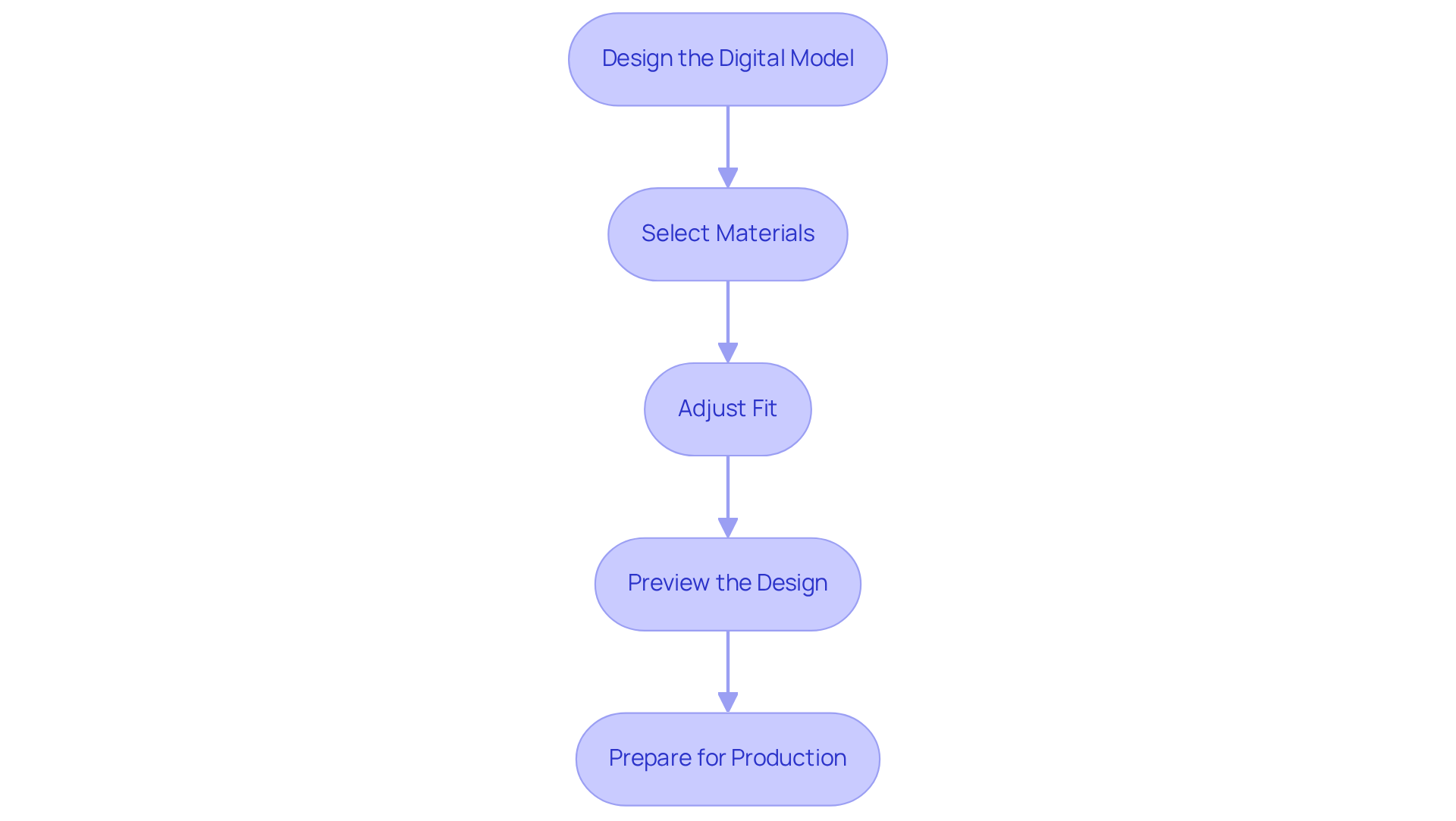

- Design the Digital Model: Utilize advanced CAD software to create a digital representation of your dental prosthetics based on the impressions. This technology allows for precise customization, ensuring a fit that mirrors the unique contours of your mouth.

- Select Materials: Choose the suitable resin and color for your dental prosthetics, considering both durability and aesthetic appeal. High-quality, biocompatible materials enhance comfort and longevity, saving you up to 60% compared to local dental offices.

- Adjust Fit: Utilize the design software to make essential modifications, ensuring that the prosthetics will fit snugly and comfortably. This step is vital, as personalized dental appliances significantly lower the risk of irritation and sore areas compared to conventional choices.

- Preview the Design: Employ 3D visualization tools to preview the final design, allowing for any last-minute adjustments. This feature not only enhances the accuracy of the fit but also ensures that the dentures align with your desired appearance.

- Prepare for Production: Once you are satisfied with the design, ready the file for production, optimizing all settings for the selected material. The use of denture 3D printing technology streamlines production, leading to quicker turnaround times and a more efficient process.

This thorough customization procedure enables you to design dental prosthetics that not only fit flawlessly but also showcase your personal style. Your comfort is our priority, improving both comfort and confidence while enjoying the convenience of acquiring luxury dental solutions from the comfort of your home.

Send Impressions and Receive Your Custom Dentures

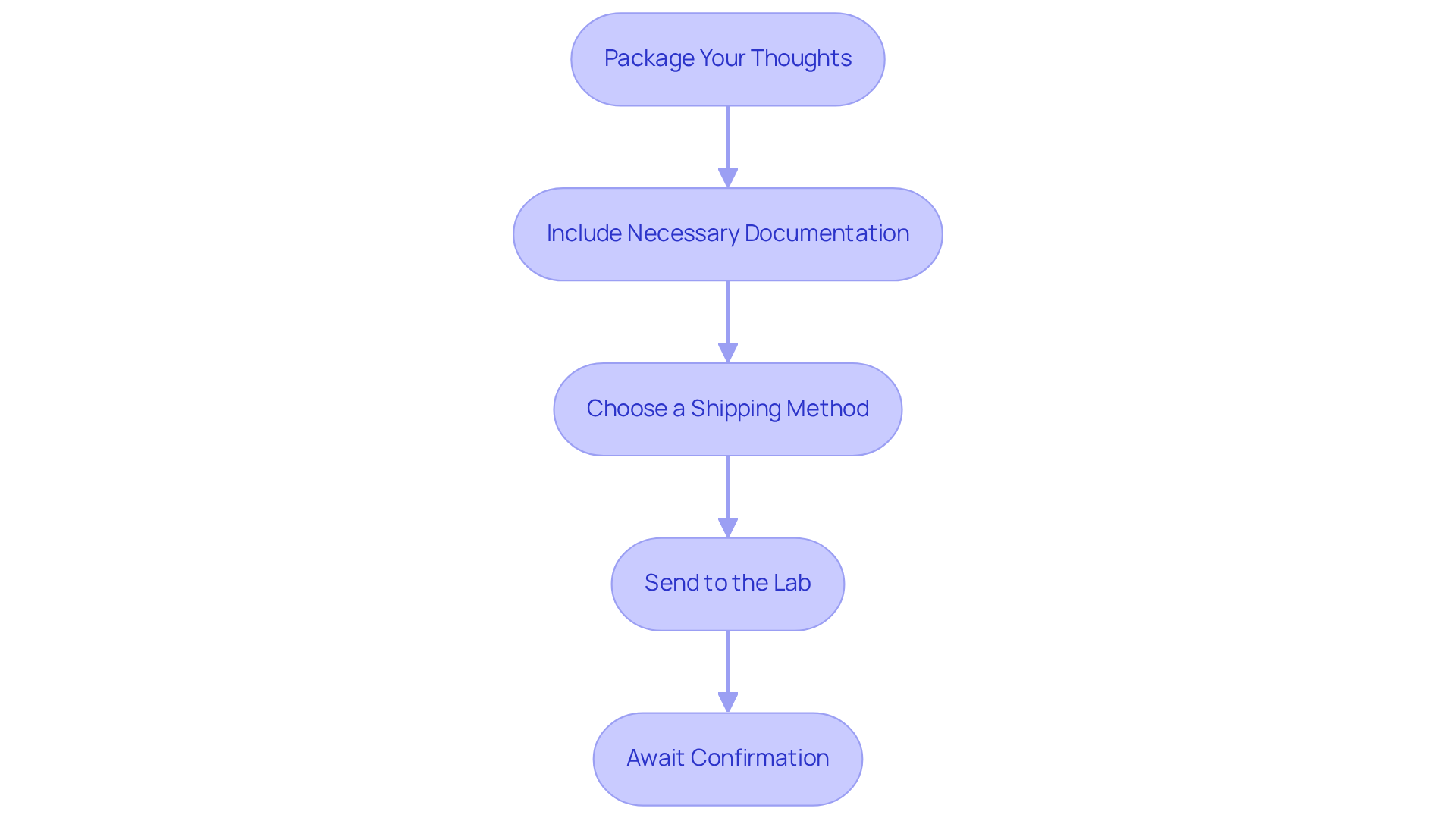

Are you tired of lengthy dental visits? To successfully send your impressions and receive custom dentures, follow these essential steps:

- Package Your Thoughts: Securely place your thoughts in a crush-proof box, using foam or bubble wrap to protect them from compression and temperature fluctuations during transit.

- Include Necessary Documentation: Attach any required forms or notes that detail your customization preferences. This ensures the lab has all the information needed to create your dentures.

- Choose a Shipping Method: Opt for a reliable shipping service that provides tracking capabilities. This allows you to monitor the delivery of your prints to the lab.

- Send to the Lab: Mail your package promptly to the designated dental lab to avoid unnecessary delays in processing your order.

- Await Confirmation: After the lab receives your feedback, they will typically confirm receipt and provide an estimated turnaround time, which is usually between 5-7 business days for most cases.

At DentKits, we understand that comfort is key. We utilize state-of-the-art imaging cameras to create a precise 3D model of your teeth and gums from your impressions. A U.S. in-state licensed oral care professional will evaluate and recommend your custom-designed false teeth, which are then created using denture 3D printing technology. As Dr. Johan Goosen, a dental implant surgeon, emphasizes, “Accuracy in the initial phases of prosthesis creation is essential for obtaining the best outcomes.”

By adhering to these guidelines, you can ensure that your custom dentures are crafted with precision and care. Your comfort is our priority, facilitating a seamless transition from impression to final product.

Conclusion

Are you tired of lengthy dental visits? Creating custom dentures at home through 3D printing is a revolutionary shift in dental care that can help you bypass those long waits while achieving a personalized and comfortable fit. This innovative method streamlines the process and utilizes advanced technology to ensure that your dentures are tailored to the unique contours of your mouth, enhancing both functionality and aesthetics.

Throughout this article, we’ve shared key insights on:

- The essential materials and tools required

- The step-by-step process for taking accurate impressions

- The customization options available to ensure a perfect fit

It’s crucial to emphasize the importance of precision in each stage, from preparing the mold to sending impressions to the lab. This attention to detail ultimately leads to the creation of high-quality, custom dentures that meet professional standards.

The significance of embracing denture 3D printing cannot be overstated. It empowers you to take charge of your dental health and comfort, transforming the often daunting experience of obtaining dentures into a more manageable and satisfying journey. By leveraging this advanced technology, you can enjoy the benefits of personalized dental solutions, paving the way for improved confidence and quality of life.

Your comfort is our priority. We understand that making the switch to custom dentures can feel overwhelming, but with the right tools and guidance, it can be a smooth process. So why wait? Take the first step towards a more comfortable and confident smile today!

Frequently Asked Questions

What is 3D printed dentures?

3D printed dentures are dental prosthetics created using advanced digital technology, allowing for accurate customization tailored to an individual’s unique oral anatomy. This method significantly reduces the need for multiple fittings and adjustments compared to traditional dentures.

How does the process of creating 3D printed dentures work?

The process begins with a digital scan of the patient’s mouth, which creates a detailed model. This model guides the layer-by-layer fabrication of the dentures using biocompatible materials, resulting in a more comfortable and precise fit.

What are the benefits of using 3D printed dentures?

The benefits of 3D printed dentures include reduced production time, enhanced visual appeal and functionality, and improved customization options for a personalized fit, leading to increased comfort for the user.

What is the projected market growth for denture 3D printing?

The denture 3D printing market for dentistry is projected to reach $7.9 billion by 2027, growing at an annual rate of 20.2%, indicating a growing preference among patients for effective oral solutions.

What materials and tools are needed to create custom dentures at home?

Essential materials and tools include a denture impression kit, a reliable 3D printer with dental-grade resin, a computer with CAD software for design, post-processing tools for finishing, and safety equipment like gloves and masks.

Why is a denture impression kit important?

A denture impression kit is crucial for capturing accurate impressions of teeth and gums, which is essential for creating precise and comfortable dentures.

What is the role of CAD software in the denture creation process?

CAD software is used to create a model of the dental appliance based on the impressions taken, allowing for precise customization to ensure a comfortable fit for the dentures.

What post-processing tools are necessary after creating dentures?

Post-processing tools include polishing kits and cleaning solutions, which are vital for ensuring the dentures are smooth and hygienic for use.

How can I ensure hygiene during the denture creation process?

Maintaining hygiene requires the use of safety equipment such as gloves and masks to protect both the individual and the materials during the denture creation process.