Overview

Are you tired of lengthy dental visits? This article provides a caring overview of how dentures are made, guiding you through the step-by-step process from taking impressions to final fittings. We understand that accurate molds and advanced technologies, such as 3D printing, are crucial for creating personalized dentures. These innovations enhance comfort and function, ultimately improving your quality of life. Your comfort is our priority, and we want you to feel supported throughout this journey.

Introduction

The journey to a confident smile often begins with a crucial yet complex process: the creation of dentures. Are you feeling overwhelmed by the prospect of dental prosthetics? Understanding how dentures are made reveals a blend of artistry and advanced technology designed to restore both function and aesthetics. This means that you are not alone in your concerns.

This article delves into the meticulous steps involved in crafting these essential dental appliances, from the initial impressions to the final fitting, highlighting how each phase plays a vital role in ensuring comfort and satisfaction. Furthermore, what challenges do patients face during this process, and how can modern techniques transform their experience? Your comfort is our priority, and we understand that navigating this journey can be daunting.

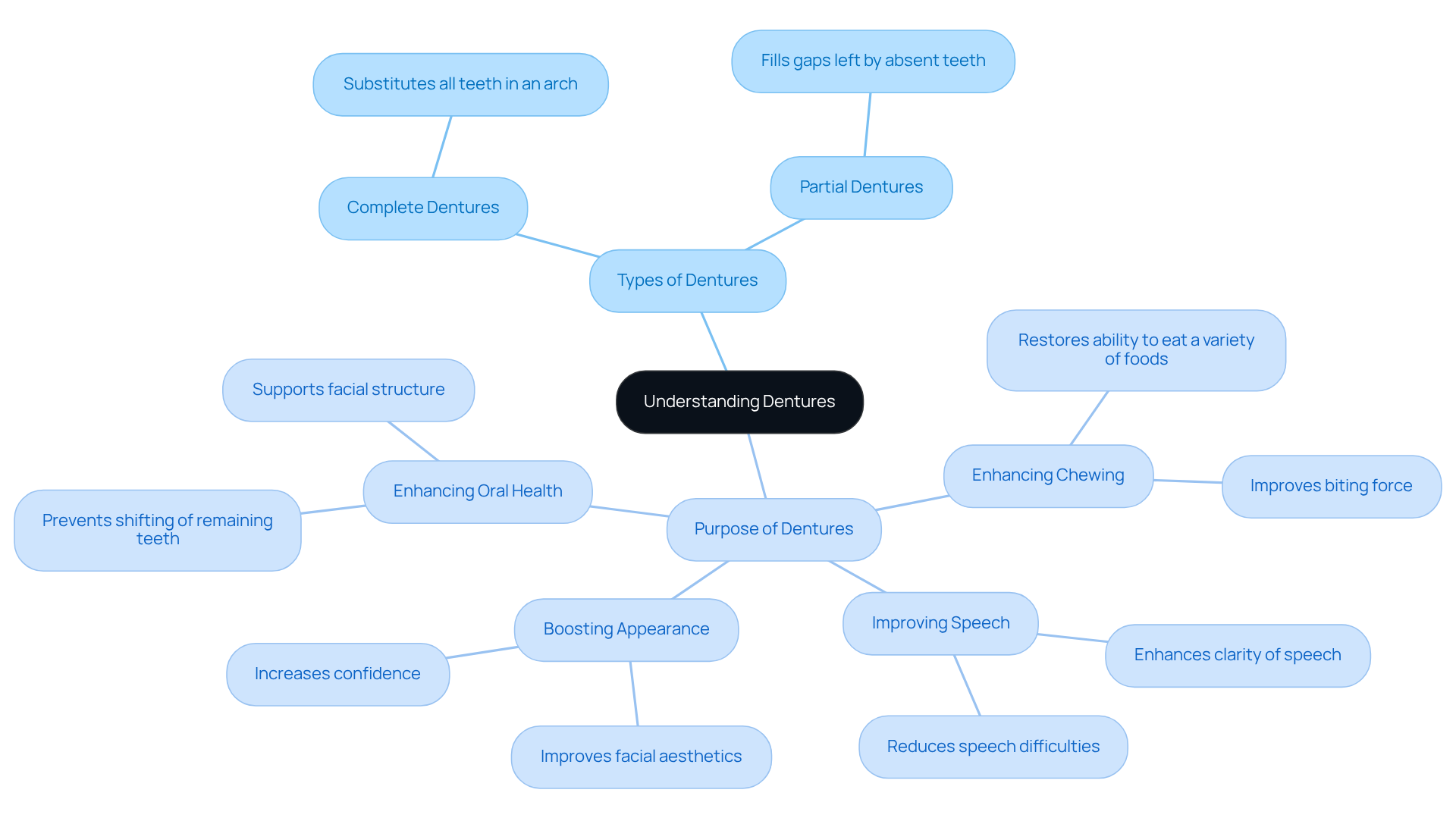

Understanding Dentures: Definition and Purpose

Are you tired of lengthy dental visits? Dentures are removable dental appliances specifically designed to replace missing teeth and restore oral function. They come in two primary types:

- Complete prosthetics, which substitute all teeth in an arch

- Partial prosthetics, which fill the gaps left by absent teeth

The main goals of dental prosthetics involve enhancing chewing capability, improving speech, and elevating overall appearance, allowing individuals to regain confidence in their smiles.

We understand that seeking dental solutions can be daunting. To understand how dentures are made, one should note that contemporary artificial teeth are crafted with cutting-edge materials and techniques, ensuring a comfortable fit and a natural appearance. This is particularly significant for those looking for luxury dental options. Studies show that more than 36 million Americans are entirely toothless, highlighting the importance of dental prosthetics in restoring not only functionality but also self-esteem. Well-fitted dental appliances can greatly enhance oral health by preventing the movement of remaining teeth, which aids in preserving proper alignment and bite. Furthermore, they can enhance facial aesthetics, supporting the structure of the face and preventing a sunken appearance.

This means that individuals who use artificial teeth often experience an increase in confidence and quality of life. These devices allow them to enjoy a broader range of foods and communicate clearly. The incorporation of modern materials, such as flexible resins and hybrid options, further improves comfort and durability, showcasing how dentures are made to be a practical and appealing choice for many. Your comfort is our priority, and we are here to .

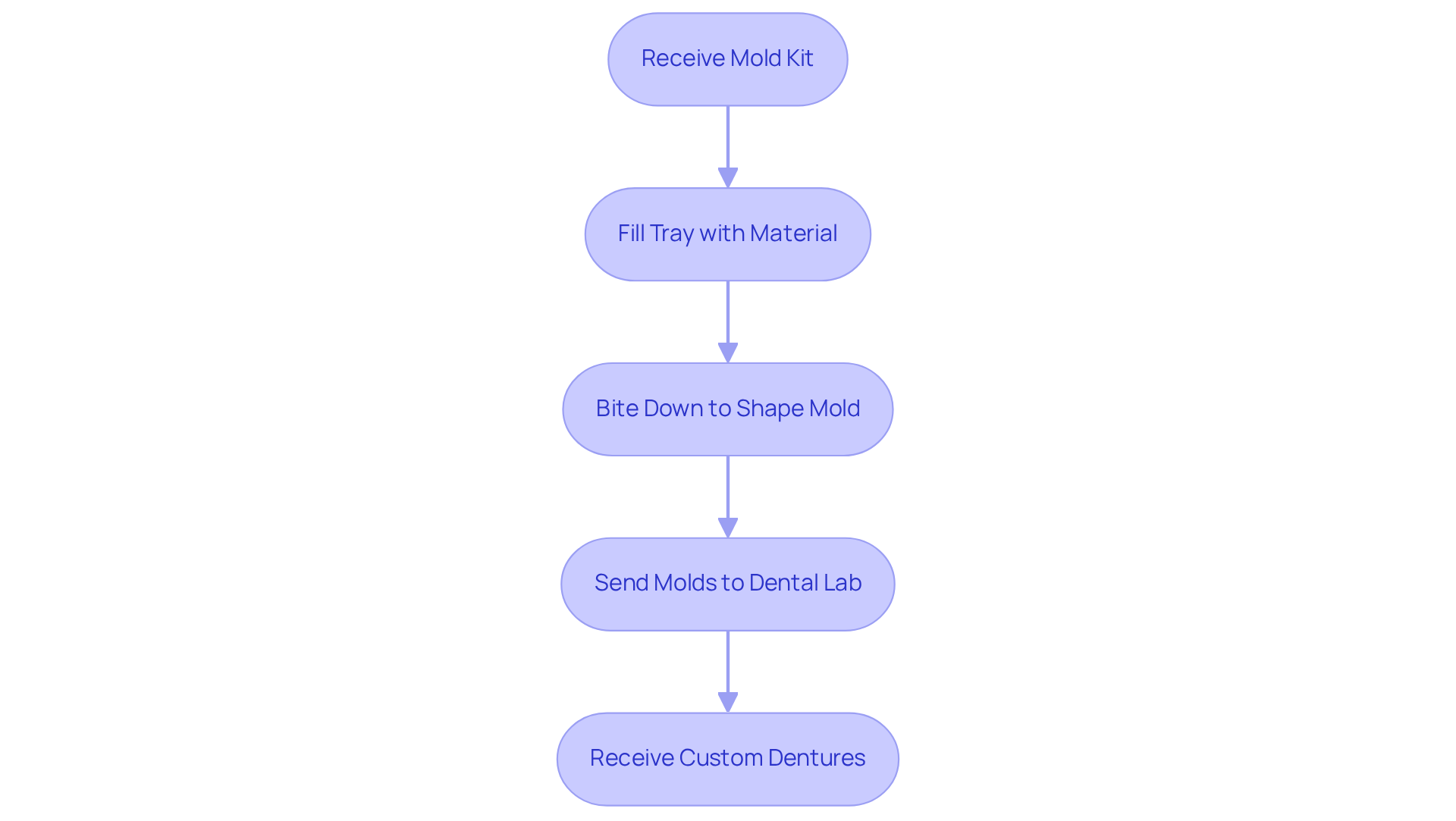

Taking Impressions: The First Step in Custom Denture Creation

The journey to custom dentures begins with the crucial step of taking dental molds, which is important for understanding how dentures are made to achieve a personalized fit. Are you tired of lengthy dental visits? Patients receive a mold kit that includes a specially designed tray and molding material, accompanied by straightforward instructions. To , simply fill the tray with the material and bite down gently, allowing it to shape to the contours of your gums and any remaining teeth. This procedure is essential; precise molds ensure that the resulting prosthetics fit securely and comfortably, reducing the chance of discomfort or slipping.

Once the molds are completed, they are sent to a dental lab for processing, which helps to explain how dentures are made. The effectiveness of personalized dental devices greatly depends on how dentures are made, especially the accuracy of these molds. Research shows that understanding how dentures are made with properly executed molds significantly improves the overall satisfaction and performance of the final product. Authorized U.S. in-state dentists play a vital role in this process, as they recommend the dental prosthetics based on the impressions obtained. Dental technicians emphasize that understanding how dentures are made requires careful attention during this stage, as even slight inaccuracies can lead to complications later in the fitting.

In fact, nearly 90% of individuals without teeth in the U.S. wear dentures, underscoring the importance of getting this initial step right. The impression-taking procedure typically takes around 30 minutes, and patients are encouraged to voice any concerns during this time to ensure optimal results. Your comfort is our priority. By employing sophisticated methods and resources tailored to the kit, DentKits strives to simplify this procedure, making it accessible and effective for busy professionals seeking high-quality oral solutions from the comfort of their homes.

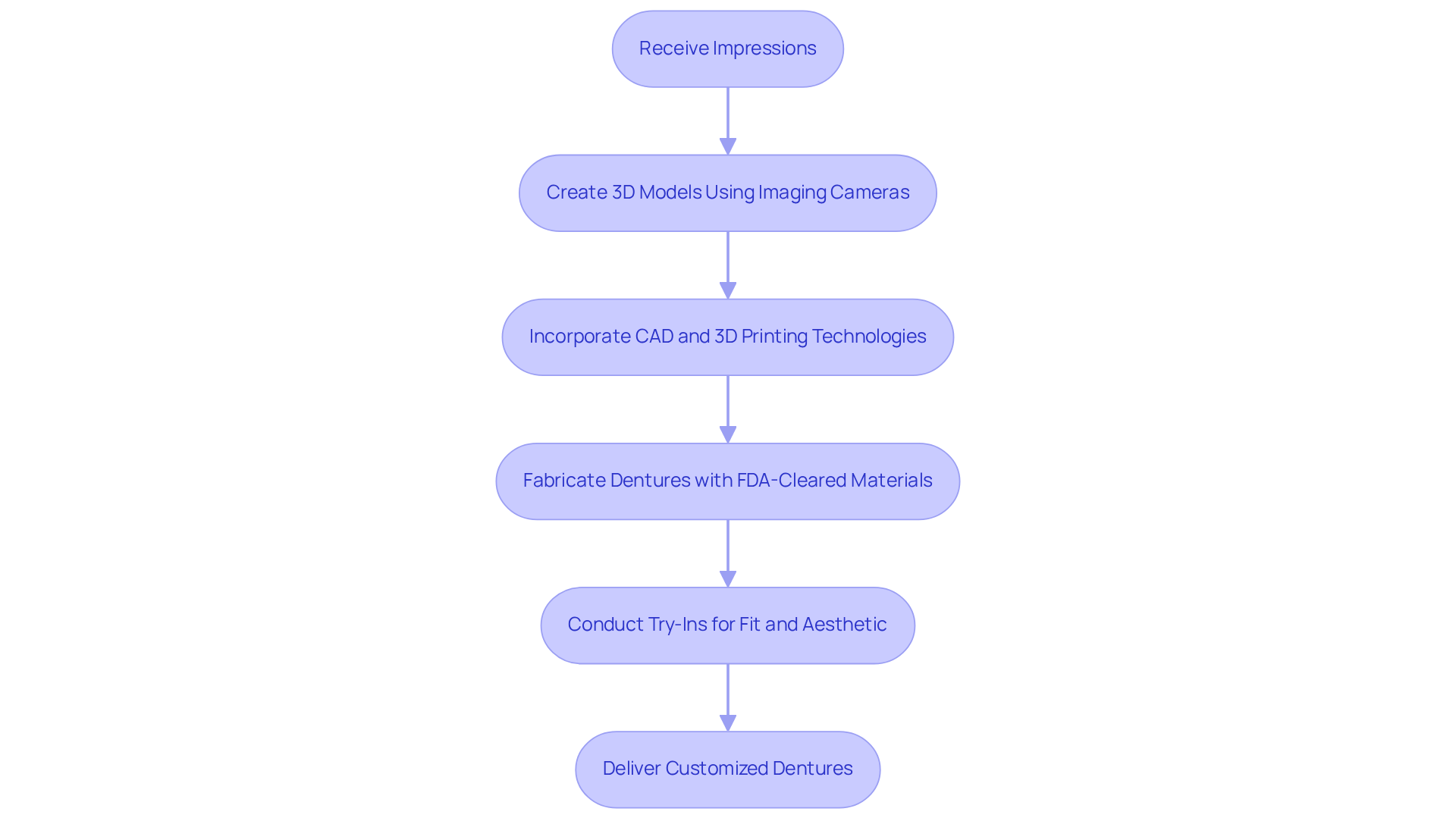

Crafting the Dentures: From Models to Advanced Technologies

Upon receiving your impressions, DentKits’ dedicated dental technicians utilize state-of-the-art imaging cameras to create precise 3D models of your mouth. This innovative digitization method serves as the foundation for understanding how dentures are made, allowing for the crafting of personalized dental prosthetics tailored to your unique anatomy. By incorporating advanced technologies, especially computer-aided design (CAD) and innovative 3D printing, we greatly enhance how dentures are made, improving both precision and efficiency in the creation process.

Are you tired of lengthy dental visits? With , we can produce solid dental appliances that are not only stronger but also more hygienic than conventional alternatives. This means that the end result closely aligns with the digital design, reducing the need for modifications and simplifying your experience. In-house printing allows us to create personalized dental appliances for approximately $100 per arch, emphasizing the affordability of this method.

The fabrication stage demonstrates how dentures are made using high-quality, FDA-cleared materials specifically designed for final prosthetics, closely mimicking the appearance and function of natural teeth to ensure a seamless aesthetic integration. This procedure often includes several iterations, such as try-ins, to help illustrate how dentures are made and to ensure that your final prosthetic teeth meet your expectations for fit and aesthetic appeal.

We understand that comfort is crucial; studies indicate that digital impressions can reduce remakes by up to 90%, leading to improved fitting restorations and heightened patient satisfaction. The accuracy of our digital design reduces pressure points and slippage in dental prosthetics, enhancing comfort for you as the wearer. Furthermore, as the 3D printing market for oral care continues to expand, expected to reach $9.5 billion by 2026, innovations in technology are transforming the field of prosthetic crafting, making it more efficient and accessible than ever before.

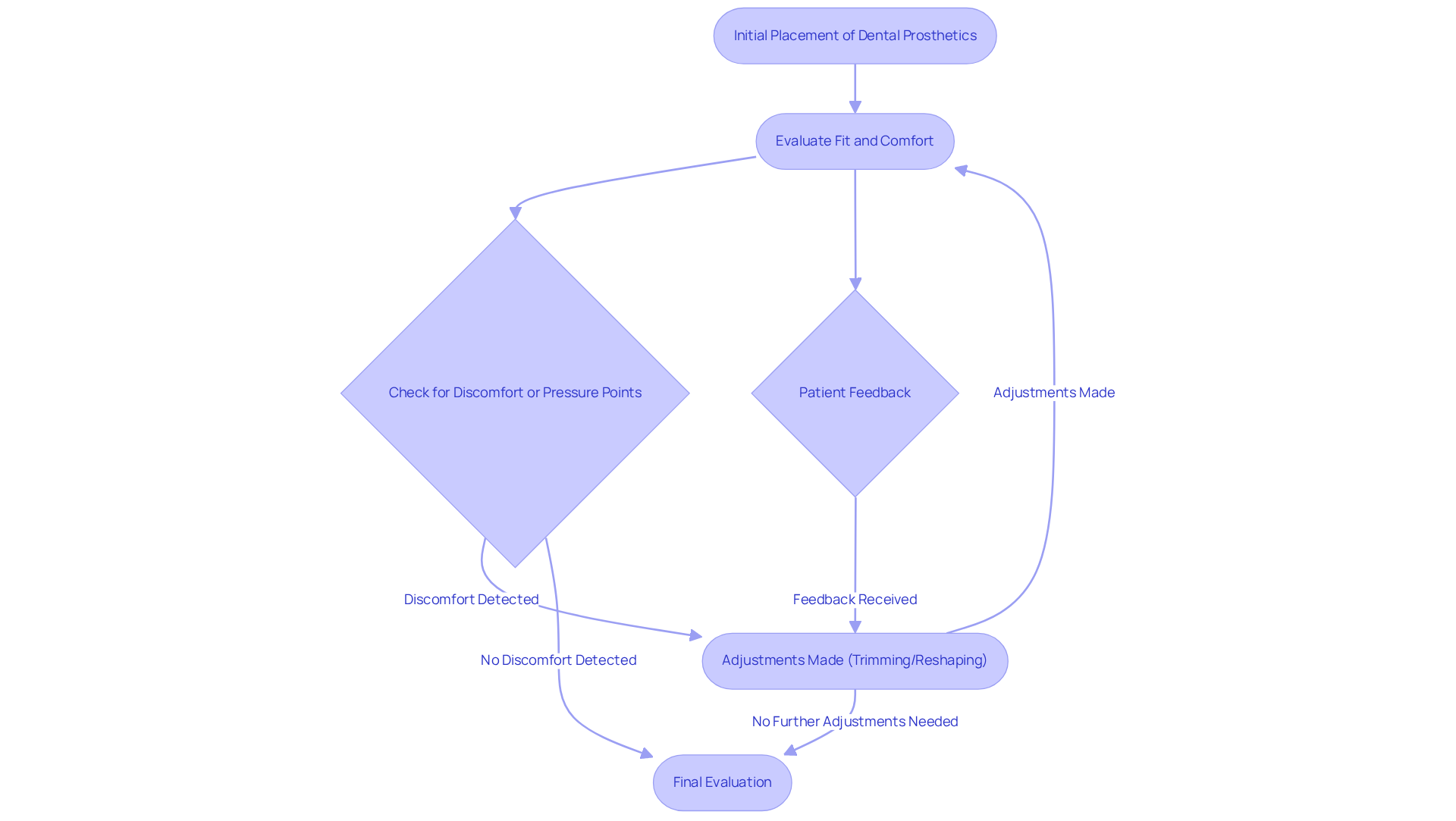

Final Fitting and Adjustments: Ensuring Comfort and Functionality

The final fitting of dental prosthetics is a crucial step that involves placing the crafted devices in the patient’s mouth to evaluate their fit and comfort, highlighting how dentures are made. Are you tired of lengthy dental visits? During this visit, the oral care specialist meticulously checks for any discomfort or pressure points, making necessary adjustments such as trimming or reshaping the prosthetics to ensure they align perfectly with the gums. Your comfort is our priority; as one dental professional noted, ‘Listening to patients about their comfort is key to .’ This collaborative approach not only enhances the fitting experience but also significantly contributes to overall satisfaction.

Common modifications made during fittings often involve:

- Refining the edges of the prostheses to alleviate pressure

- Ensuring that the bite aligns correctly

Patients are encouraged to communicate any discomfort they experience, as this feedback directly influences the adjustments made. Furthermore, once all modifications are completed, the polished and finalized dentures illustrate how dentures are made, allowing the patient to leave with a comfortable and functional smile. To maintain comfort after fitting, patients should follow proper care guidelines, including regular cleaning and periodic check-ups to address any changes in fit over time.

Conclusion

Understanding the intricate process of denture creation is essential for anyone considering these dental solutions. Are you tired of lengthy dental visits? Dentures not only restore functionality but also play a significant role in boosting self-esteem and enhancing quality of life. By grasping how dentures are made—from the initial impressions to the final fitting—individuals can appreciate the importance of each step in ensuring a comfortable and natural-looking result.

Key arguments highlighted throughout the article include:

- The types of dentures available—complete and partial prosthetics.

- The critical role of accurate impressions in achieving a perfect fit.

- Advancements in technology, such as 3D printing and digital modeling, have revolutionized the manufacturing process, allowing for greater precision and comfort.

- The final fitting stage emphasizes the importance of patient feedback in making necessary adjustments, ensuring that the dentures meet individual needs effectively.

Ultimately, the journey to a confident smile through dentures is not just about aesthetics; it is about reclaiming the ability to enjoy food, communicate clearly, and feel good about one’s appearance. Your comfort is our priority. For those exploring this option, understanding the step-by-step process of how dentures are made empowers them to make informed decisions. We understand that seeking high-quality dental solutions is essential, and we encourage you to prioritize your comfort and satisfaction.

Frequently Asked Questions

What are dentures?

Dentures are removable dental appliances designed to replace missing teeth and restore oral function.

What are the two primary types of dentures?

The two primary types of dentures are complete prosthetics, which substitute all teeth in an arch, and partial prosthetics, which fill the gaps left by absent teeth.

What are the main goals of dental prosthetics?

The main goals of dental prosthetics include enhancing chewing capability, improving speech, and elevating overall appearance, which helps individuals regain confidence in their smiles.

How are modern dentures made?

Contemporary artificial teeth are crafted using cutting-edge materials and techniques to ensure a comfortable fit and a natural appearance.

Why are dentures important for individuals who are toothless?

Dentures are important for individuals who are toothless as they restore functionality, enhance self-esteem, and allow for improved chewing and communication.

How do well-fitted dentures benefit oral health?

Well-fitted dentures prevent the movement of remaining teeth, aiding in the preservation of proper alignment and bite.

Can dentures enhance facial aesthetics?

Yes, dentures can enhance facial aesthetics by supporting the structure of the face and preventing a sunken appearance.

What materials are used in modern dentures to improve comfort and durability?

Modern dentures incorporate materials such as flexible resins and hybrid options to enhance comfort and durability.

How do dentures impact the quality of life for users?

Dentures often lead to an increase in confidence and quality of life, allowing users to enjoy a broader range of foods and communicate clearly.